|

|

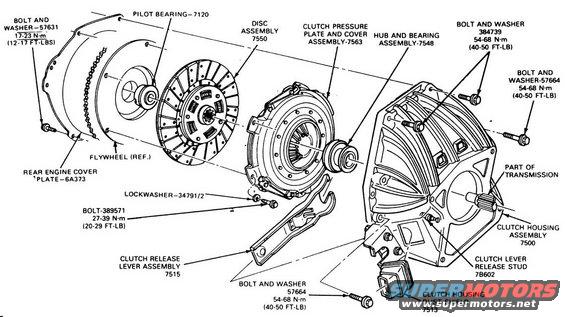

These are the parts I spent ~4 years collecting to do this swap. The hardest to find is a bellhousing since the bolt-ons with external slave were only used for ~5 years.

E4TZ-7515-C Fork (release lever)

|

|

|

Bellhousing PN.JPG | Hits: 3347 | Size: 70.84 KB | Posted on: 7/13/03 | Link to this image Bellhousing PN.JPG | Hits: 3347 | Size: 70.84 KB | Posted on: 7/13/03 | Link to this image

This is the one I found - apparently from an '84-86.

|

|

|

This is the clutch set for an '86 4-speed, and it includes the throwout and pilot bearings. UPDATE: it lasted almost exactly 10 years to the day. I'll probably replace it with an LuK 07-031 since I can't use the 07-909 (commercial) which is built for the later concentric slave.

|

|

|

These are the main reasons I hate the mechanical linkage: all these parts (except the equalizer bar) were BRAND NEW FORD parts about 4 years ago, and they're already worn out. The boot dry-rotted within ~2 years and the plastic bearings inside the equalizer are probably not much better. I even added a grease fitting to it to try to keep them from wearing.

|

|

|

Just one of MANY reasons why this mechanical linkage sucks.

|

|

|

Another of the MANY reasons this mechanical linkage sucks.

|

|

|

Here's the mechanical bellhousing's last few moments on my truck.

|

|

|

The flywheel shows signs of slipping and maybe oil contamination, but not too bad. This is the original '95 flywheel that was on the engine when I swapped IT in ~4 years ago. UPDATE: This is how it looked 10 years later:

|

|

|

All the new (old) stuff bolts right on.

|

|

|

Since the '82 body wasn't marked for the hydraulic master cylinder (like every later body), I had to locate it by holding the reinforcement plate against the inside of the firewall and drilling through. Then I used the gasket to mark the 2 stud holes, and a hole saw to cut the main hole.

|

|

|

The rusty part is the reinforcement plate, and it's pressed as far up & inboard as it can go and stay flat against the firewall. The large vacuum line in the top R used to go to the cruise brake cancel valve, but now goes to my vacuum gauge.

|

|

|

Unfortunately, it seems I scavenged a later-style system because this slave is made for bellhousings with a casting boss on the aluminum instead of a bolt-on steel bracket.

|

|

|

After a quick trip to the parts store in my gf's MGB, I had the correct slave bled & installed.

|

|

|

Now, the hard part begins: my clutch pedal shaft has slots at both ends, but the lever made for that AND the hydraulic linkage isn't available. '84-86 Clutch Pedal Lever Ford E7TZ7A554A

|

|

|

So I figured out how to put a square shaft into a round hole. After figuring the angle that the '86 lever needed to sit on the '83 shaft, I clamped them together.

|

|

|

I drilled a small hole in each corner - about 1/8".

|

|

|

Then I cut out as much as I could with my Stanley Contractor Grade hacksaw (the best for several reasons).

|

|

|

Then I filed it out to the right shape, checking frequently to keep it tight on the shaft.

|

|

|

I was pretty happy with how it came out. But after driving it for a week, I realized I had cut the slot at the wrong angle and the metal was wearing. When it's made at a factory, the punching process work-hardens the steel around the edge, but my filing process hadn't done that, so the hole was slowly rounding. All that effort was wasted.

|

|

|

The only solution was a later pedal shaft with splines, so I found an '86 shaft & pedal. The '87 lever is totally wrong.

|

|

|

The '86 pedal uses a different cruise clutch kill switch, but mine will still work with it. The pedal also has a brace to keep it from hitting the firewall because '84-86 5.0L EFIs have the inertia switch there.

|

|

|

When I compared the pedals, the spring bracket seemed different.

|

|

|

Looking closer, I could see that the '86 spring bracket was welded on at a noticeable angle.

|

|

|

I figured this was to adjust the way the pedal spring affects the master cylinder's return & self-adjusting operation.

|

|

|

Other than the lever end, the shafts are identical.

|

|

|

When I replaced the body, I noticed this hole and wondered why it was there - now I know!

The copper sleeve at the top of the gas pedal takes up the slack in the cable so I have better throttle response & can actually get it all the way open.

|

|

|

Reinstalling this spring was VERY difficult: I used a special clamp to compress it, and then tied it with baling wire to hold it compressed. Then I could install it with no pressure, and cut the wire to release it in position. I also had to remove the fuse block for working room.

|

|

|

Lever & Bushings.JPG | Hits: 5551 | Size: 114.12 KB | Posted on: 7/14/03 | Link to this image Lever & Bushings.JPG | Hits: 5551 | Size: 114.12 KB | Posted on: 7/14/03 | Link to this image

Even with the right shaft, my slotted '86 lever was too far gone to reuse, so I had to order a new one. Because spline alignment is so critical, Ford recommends changing this lever every time the master cylinder is changed. The plastic bushing is also critical, because the MC pushrod eye is oversized. I bought some extras... The lever for '83-older mechanical is E1TZ7A554A . The lever for '84-97 hydraulic is E7TZ7A554A . The '84-86 bushing is D6TZ7526B . The '87-97 bushing is E69Z7526A and is included in Dorman 14041.  For more info on replacing this lever, read these captions:  .

|

|

|

Just before heading off to RITS09, a shiny piece of metal fell onto my foot, and after that, it was VERY difficult to shift without grinding. Turns out this '80-83 pedal bracket couldn't take the load of a hydraulic clutch linkage. So after going to all the trouble of swapping in the '84-86 clutch pedal shaft & lever, I now have to swap in a whole '84-86 pedal assembly. '87-91 is substantially different: the column mounting holes are farther apart, and the casting doesn't reach as high below the w/s. The '87-91 clutch pedal also lacks the welded tab for the clutch switch since those years use a wraparound switch on the clutch master cylinder pushrod.

|

|

|

Just before heading off to RITS09, a shiny piece of metal fell onto my foot, and after that, it was VERY difficult to shift without grinding. Turns out this '80-83 pedal bracket can't take the load of a hydraulic clutch linkage because it's pushing forward instead of down, the way the older mechanical linkage does. So after going to all the trouble of swapping in the '84-86 clutch pedal shaft & lever, I now have to swap in a whole '84-86 pedal assembly. '87-91 is substantially different: the column mounting holes are farther apart, and the casting doesn't reach as high below the w/s. The '87-91 clutch pedal also lacks the welded tab for the clutch switch since those years use a wraparound switch on the clutch master cylinder pushrod.

|

|

|

The same pedal bracket is used for mechanical & hydraulic clutches from '80-86, but the clutch pedal, shaft, lever, & switch changed in '84 for the hydraulic system. The bracket & switch changed again in '87, and the bracket changed again in '92 to a cast Aluminum column & e-brake mount with a separate steel pedal bracket.

I'm transferring the switch, spring, & pedal pads onto the new pedals, and installing a new lever (since the splines can only be cut once).

|

|

|

Amazing how much better it works when the bracket is all there.

|

|

|

Hydraulic Clutch Linkage To determine if the clutch master cylinder push rod and cross-shaft lever pin are in the correct relationship, disconnect the push rod and note if it will reassemble to the pin. When the pushrod is disconnected from the pin, the clutch master cylinder piston is fully retracted rearward and the clutch pedal blade is contacting the rubber bumper up stop. If the two components are not in alignment, perform the following only in this sequence: 1. Tighten left side clutch pedal attaching nut left side. 2. Install clutch master cylinder push rod to the cross-shaft lever pin. 3. Stroke clutch pedal several times to reset position of shaft to pedal slot. (NOTE: Step 4 is mandatory.) 4. Again, remove the clutch master cylinder push rod from lever pin and evaluate alignment. If the two components are still not in alignment, replace the cross-shaft lever. If the push rod is aligned with the pin, no further action is required.  Clutch Pedal Lever Removal (~'87-96) 1. Disconnect clutch master cylinder push rod from clutch and brake pedal pivot shaft lever pin. Use a small screwdriver or putty knife to wedge between lever and snap-in bushing. 2. Remove attaching nut. 3. Pry lever from clutch and brake pedal pivot shaft. Installation (~'87-96) NOTE: ALWAYS install a new shaft lever following any service on the clutch master cylinder or brake and clutch pedal assembly. Failure to do so could result in improper master cylinder push rod initialization, leading to premature clutch failure. 1. Snap the new lever (pin) to the clutch master cylinder push rod bushing. 2. Install lever onto clutch and brake pedal pivot shaft. 3. Finish tightening down clutch master cylinder, pedal bracket or brake booster if required. 4. Install attaching nut finger-tight. 5. Inspect clutch pedal position. Make sure it is against the "up" stop. 6. Tighten attaching nut allowing knurled teeth on clutch and brake pedal pivot shaft to cut matching teeth in lever for correct positioning. For more info on lever replacement, read this caption:  For more info on clutch diagnosis, read this caption:  For clutch pedal box wear, read this page:

|

|

|

Pre-'84 Mechanical Clutch Linkage Equalizer (Z) Bar

|

|

|

Bellhousing Hyd.jpg | Hits: 4676 | Size: 54.26 KB | Posted on: 7/14/03 | Link to this image Bellhousing Hyd.jpg | Hits: 4676 | Size: 54.26 KB | Posted on: 7/14/03 | Link to this image

Hydraulic Clutch & bellhousing for '84-89 with external slave

E4TZ-7515-C Fork (release lever)

|

|

|

BellhousingHydr84.jpg | Hits: 283 | Size: 47.66 KB | Posted on: 1/13/22 | Link to this image BellhousingHydr84.jpg | Hits: 283 | Size: 47.66 KB | Posted on: 1/13/22 | Link to this image

'84-89 Bellhousing for External Hydraulic-Slave IF THE IMAGE IS TOO SMALL, click it. Sandblasted & painted DupliColor DE1650  .  .  .

|

|

|

Clutch Linkage Hyd.jpg | Hits: 7462 | Size: 39.99 KB | Posted on: 7/14/03 | Link to this image Clutch Linkage Hyd.jpg | Hits: 7462 | Size: 39.99 KB | Posted on: 7/14/03 | Link to this image

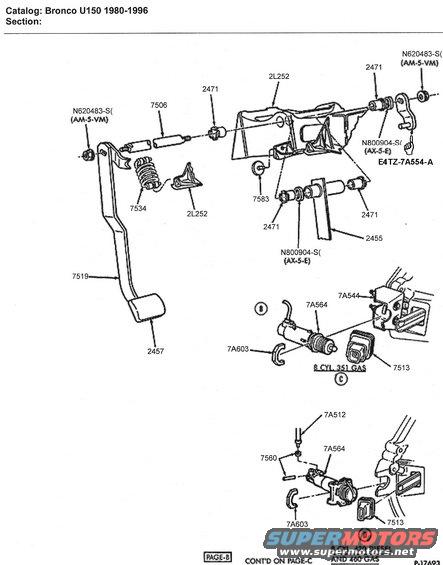

Hydraulic Clutch Pedal for F-Series and Bronco with 4.9L and 5.0L Engines (T-18 Transmission)

1. With the clutch pedal fully depressed to the floor, measure the external slave cylinder push rod travel.

2. The push rod should extend 17mm (0.67 inch) minimum. Do not replace the clutch system if the measurement exceeds this distance.

3. If release bearing travel does not meet the travel requirements check the reservoir fluid level.

NOTE: The slave cylinder must be in place when checking the fluid level. The proper level is indicated by a step on the reservoir.

4. Fill to the specified level with Ford Heavy Duty Brake Fluid C6AZ-19542-AA or -BA (ESA-M6C25-A) or equivalent DOT 3 fluid. Do not overfill. The upper portion of the reservoir must accept fluid that is displaced from the slave cylinder as the clutch wears.

CAUTION: Carefully clean the top and sides of reservoir before opening to prevent contamination of the system with dirt, water and other foreign material. Remove reservoir diaphragm when checking or adding fluid. Carefully replace diaphragm, cover gasket and cover after filling.

5. If the reservoir requires fluid, check hydraulic system components for leakage.

6. Remove rubber boots from cylinder and check for leakage past the pistons. A slight wetting of surfaces is acceptable. If excessive leakage is evident, replace leaking component.

|

|

|

Clutch Switch Details '80-86

|

|

|

Clutch Hydraulic.jpg | Hits: 9344 | Size: 57.92 KB | Posted on: 9/15/05 | Link to this image Clutch Hydraulic.jpg | Hits: 9344 | Size: 57.92 KB | Posted on: 9/15/05 | Link to this image

'92-96 Hydraulic Clutch External Slave Cylinder Bleeding

1. Clean reservoir cap and cylinder clutch slave in area of the tube connection.

2. Remove cylinder clutch slave from the transmission bell housing.

3. Use a 3/32-inch diameter punch to drive out tube holding pin.

4. Remove the tube from the cylinder clutch slave and place tube end into a container for waste fluid.

NOTE: The tube is connected to the clutch master cylinder, so keep the clutch master cylinder reservoir cap tight to minimize fluid loss.

5. Hold cylinder clutch slave so connector port is at highest point, by tipping cylinder clutch slave to approximately 30 degrees. Fill with approved DOT 3 brake fluid through connector port.

NOTE: It may be necessary to "rock" cylinder clutch slave around or push gently on push rod to expel all the air. Pushing on push rod too hard will cause fluid to spray out of the connector hole.

NOTE: Do not allow any moisture or foreign matter to enter slave with brake fluid.

6. When all the air is expelled from the cylinder clutch slave and no more bubbles come out of the port hole, install cylinder clutch slave.

NOTE: Fluid is expelled from the connector port as the push rod is compressed, attaching it to the transmission and clutch release shaft.

7. Gravity fill the clutch master cylinder and tube as follows.

- Remove the clutch master cylinder reservoir cap and diaphragm.

- Fluid should flow out the open end of the tube into waste container. Be sure to keep the clutch master cylinder reservoir full.

- When fluid is flowing out in a steady, uninterrupted flow and fluid is level with step in clutch master cylinder reservoir, install cap and diaphragm.

- Install end of tube into cylinder clutch slave.

- Replace pin holding tube to body of cylinder clutch slave.

- Remove the slave cylinder from the transmission.

- Holding the cylinder so that the port for the tube is at the highest point, slowly push the pushrod into the cylinder and slowly let it return. Be sure the reservoir is full of fluid beforehand. Repeat this step two more times.

- Reattach the slave cylinder to the transmission.

- Rapidly depress the clutch pedal 10 times through a travel of approximately 1 inch. Wait two minutes.

- If the pedal is not hard within .25 inch to .5 inch of travel, repeat Step D.

8. System should be bled and functioning properly.

- To verify proper system function, set parking brake control (2780) and put vehicle in neutral.

- Start vehicle and shift into reverse gear.

- If gears grind, other components may be causing the concern.

- Check cylinder clutch slave push rod travel as described in this section.

Alternate Method

1. Gravity bleed system in place.

NOTE: If clutch release shaft cannot be moved toward front of vehicle, the clutch cable bracket is incorrectly set. Replace lever. Refer to «clutch master cylinder push rod» adjustment procedure in this section.

2. From under vehicle, with cylinder clutch slave bleed port closed, push external part of release lever slowly toward front of vehicle and release. Repeat this cycle 10-15 times until you no longer hear bubbles in the clutch master cylinder.

|

|

|

Clutch ConcSlave.jpg | Hits: 23862 | Size: 40.98 KB | Posted on: 9/15/05 | Link to this image Clutch ConcSlave.jpg | Hits: 23862 | Size: 40.98 KB | Posted on: 9/15/05 | Link to this image

Concentric Slave Cylinder 9L5Z-7A508-A Bleeding IF THE IMAGE IS TOO SMALL, click it. 1. Disconnect the coupling at the transmission with Coupling Disconnect Tool T88T-70522-A or equivalent by sliding the white plastic sleeve toward the slave cylinder while applying a slight tug on the clutch tube. 2. Clean dirt and grease from around the reservoir cap. 3. Remove cap and diaphragm and fill reservoir to the step with Heavy Duty Brake Fluid C6AZ-19542-AA or -BA (ESA-M6C25-A) or equivalent. Brake fluid must be certified to DOT 3 specification. By hand, apply 10-15 pounds to clutch pedal; if pedal is hard (.25-.50 inch) movement, skip to Step 9. If pedal is spongy, proceed to next step. 4. Using a small screwdriver, depress the internal mechanism of the male coupling to open the valve. While continuing to hold the valve open, slowly depress the clutch pedal to the floor and hold. 5. Remove the screwdriver from the coupling, closing the valve. 6. Release the clutch pedal. NOTE: The reservoir must be kept full at all times to ensure there will be no additional introduction of air into the system. 7. Refill reservoir to level at step. 8. Repeat steps 4 through 7 one time. 9. Close reservoir. Reconnect the coupling to the slave cylinder. Check that the connection is secure by applying a slight tug to the clutch tube. 10. Stroke the clutch pedal as rapidly as possible for five to ten strokes. 11. Wait one to three minutes. 12. Repeat Steps 10 and 11 three more times. 13. Loosen bleed screw (located in the slave cylinder body next to the inlet connection). 14. Depress and hold clutch pedal while tightening bleed screw 3-5 N-m (2.2-3.7 ft-lb). 15. Refill the reservoir to level at step. 16. The hydraulic system should now be fully bled and should properly release the clutch. -------------------------------------------------------------------------------- See also:  .  .  .  .  .  .  .  .

|

|

|

I needed another transmission as a spare, and the junkyard cut me a deal on the whole mess. I plan to use the transmission, and I'll probably keep the transfer case as a spare, but the rest is SOLD.

E4TZ-7515-C Fork (release lever)

|

|

|

This is the bellhousing needed to mount an external slave.

I didn't notice until LONG after cleaning it that it's severely cracked between the slave mount & the fork (release lever E4TZ-7515-C).

|

|

|

This is the bellhousing needed to mount an external slave. I didn't notice until LONG after cleaning it that it's severely cracked between the slave mount & the fork.

|

|

|

Master & slave cylinders still sealed & full of fluid.

|

|

|

I got these from a truck whose cab had been swapped, but I think they're '84 parts. The starter interrupt switch is attached, and can be connected to a cruise module.

|

|

|

BellhousingHydr.JPG | Hits: 3207 | Size: 76.44 KB | Posted on: 9/15/07 | Link to this image BellhousingHydr.JPG | Hits: 3207 | Size: 76.44 KB | Posted on: 9/15/07 | Link to this image

I didn't notice until LONG after cleaning it that it's severely cracked between the slave mount & the fork. Leo Goff (known for antique motorcycle restoration) welded it up for me.

|

|

|

Clutch Fluid Filling

IF THE IMAGE IS TOO SMALL, click it.

It's not apparent because it's black rubber, but the diaphragm that protects the clutch fluid from the air's humidity must be REMOVED from the master cylinder reservoir before the fluid level can be checked or adjusted. There should never be fluid on top of (inside) the diaphragm.

|

|

|

ClutchResDiaphragm.JPG | Hits: 9553 | Size: 59.2 KB | Posted on: 9/24/07 | Link to this image ClutchResDiaphragm.JPG | Hits: 9553 | Size: 59.2 KB | Posted on: 9/24/07 | Link to this image

The mythical, elusive diaphragm. Many people don't realize that this MUST be removed before checking/adding brake fluid to the clutch master cylinder reservoir. So it can often be found full of fluid above an empty reservoir. The inside if this diaphragm should be DRY, and the fluid should reach the step molded into the wall of the master cylinder reservoir.  .

|

|

|

Clutch Lever 83.JPG | Hits: 2658 | Size: 80.09 KB | Posted on: 6/21/05 | Link to this image Clutch Lever 83.JPG | Hits: 2658 | Size: 80.09 KB | Posted on: 6/21/05 | Link to this image

SOLD New clutch pedal lever for '83-older with mechanical linkage

The lever for '84-86 hydraulic is E4TZ7A554A .

The lever for '87-97 hydraulic is E7TZ7A554A .

|

|

|

ClutchPedalPosSw.jpg | Hits: 9098 | Size: 52.03 KB | Posted on: 7/5/12 | Link to this image ClutchPedalPosSw.jpg | Hits: 9098 | Size: 52.03 KB | Posted on: 7/5/12 | Link to this image

Clutch Pedal Position Switch '87-96 is installed on the clutch MC pushrod above the gas pedal. 1 - Lock Tabs (part of Retainer Plate) 2 - Retainer Plate 3 - Catch (part of Clutch Master Cylinder) 4 - Pushrod (part of Clutch Master Cylinder) 5 - Clutch Pedal Position (CPP) Switch Motorcraft SW5993 or Standard NS1276 - Connector 261 (part of Harness 14404) 7 - Catch Boss (part of CPP) 8 - Clutch Master Cylinder Removal 1. Disconnect the wiring harness (#6) from clutch pedal position switch (CPP) (#5, 11A152). 2. Pull down on orientation clip (#3) to separate from switch tab (#7). 3. Rotate clutch pedal position switch (#5) one-half turn to expose plastic retainer (#2). 4. Push lock tabs (#1) together and slide retainer (#2) rearward and separate from clutch pedal position switch (#5). 5. Remove clutch pedal position switch (#5) from clutch master cylinder (7A543) push rod (#4). Pin - Circuit - Function 1 - 32 R/LB - Ig.Sw. START to CPP 2 - 32 R/LB (or 33 W/Pk) - CPP to THEFT (option '94-95 only), or Starter Relay & 480 Pu/Y 3 - 306 LG or R/LG or T/LB - CPP to Cruise (Vehicle Speed Control) 4 - 511 LG - Brake Lamps & BOO to CPP 5 - 480 Pu/Y (or Gy/Y) - 32 R/LB to CPP 6 - 481 LB/Y or Gy/Y - CPP to EEC pin 30 (START input) Pin numbers are reversed for '96-up. LOGIC Pins 1-2: NO - Ig.Sw. to starter relay interrupt Pins 3-4: NC - VSC (cruise) ground input (enable) Pins 5-6: NO - EEC input (idle strategy) Switch Removal: 1) squeeze lock tabs 2) slide retainer plate rearward 3) depress catch (if present) 4) slide CPP down & rearward off of pushrod  .  .  .  .  The jumper used with automatic transmissions closes 1&2, 3&4, 5&6.

|

|

|

Clutch Pedal Position (CPP) Switch Jumper & other '92-96 dash features IF THE IMAGE IS TOO SMALL, click it. Although not shown in the EVTM's wiring diagrams, trucks with auto trans use a jumper in the CPP connector, which is stored on the front of the dash structure above the accelerator pedal.  .  The unnamed connector (C2??) is in the return (ground) circuit between Splice 207 (for the instrument cluster, ig.sw., & HVAC illumination) and Splice 202 (ultimately leading to G201).

|

|

|

SOLD Clutch Master Cylinders

|

|

|

SOLD Clutch Pedal Assembly for '87-91

IF THE IMAGE IS TOO SMALL, click it.

For more info on replacing the lever, read these captions:

.

|

|

|

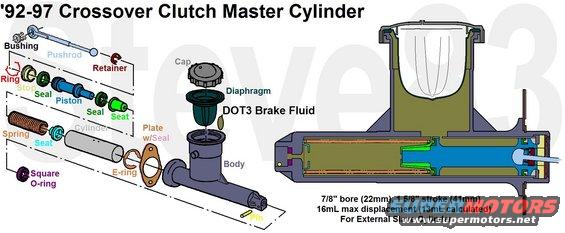

'84-91 Clutch Master Cylinder exploded

|

|

|

ClutchMasterCyl.jpg | Hits: 1733 | Size: 35.9 KB | Posted on: 3/12/16 | Link to this image ClutchMasterCyl.jpg | Hits: 1733 | Size: 35.9 KB | Posted on: 3/12/16 | Link to this image

'84-91 Clutch Master Cylinder IF THE IMAGE IS TOO SMALL, click it. See also:  .  .

|

|

|

The middle design ( LuK LMC176; ( Dorman CM350033; Sachs SH5062; AMS M0713) combines the volume of the old design with the mounting of the new design for '92-97 trucks with older external-slave transmissions. UPDATE: That black bushing ( Dorman 74014) in the aftermarket pushrod lasted about 3Kmi (less than a year of normal driving), but Ford still offers it as 6C3Z7A581A.  UPDATE: The white Ford bushing didn't last any longer - turns out the pedal shaft bushing (F3TZ2C342A) was worn out, causing the shaft to be misaligned, putting side force on that bushing's retainers. But even repairing the shaft bushing didn't prevent a 3rd pushrod bushing from sliding off, so I drilled & pinned the pushrod to the pedal lever. The entire clutch/brake pedal assembly (Ford F3TZ2455A) is still available new.

|

|

|

ClutchMasterCxl.jpg | Hits: 967 | Size: 36.13 KB | Posted on: 3/12/16 | Link to this image ClutchMasterCxl.jpg | Hits: 967 | Size: 36.13 KB | Posted on: 3/12/16 | Link to this image

'92-97 Clutch Master Cylinder for older (external slave) transmissions

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

Early Clutch Master Cylinders

The older MC moves more fluid than the newer, and it mounts differently.

|

|

|

'92-96 Clutch Master Cylinder exploded

The spring & forward plunger block off the reservoir when the MC is not fully-released. The piston & O-ring in the middle are the ones that move the fluid to the slave.

The mounting plate's index is larger than the key on the MC body to allow the MC to be twisted sideways for easier access to the mounting nuts.

|

|

|