Bigger Lungs For GM's Iron Beast

aFe Steps Up With An Intake For The '06 Duramax LBZ

By: Leonard Strathern

Every year, for the last few years we have anxiously awaited the release of each of the big three's newest and most powerful diesel light-trucks (Chevy, Ford and Dodge). As the technology of diesel engines improve so does its power and efficiency. In late 2005, Chevrolet introduced it's most powerful diesel to date: the LBZ 6.6 Duramax. Producing 360 horsepower and 650 ft-lb. of torque with a reduced compression ratio was no doubt a tricky task for the diesel brains at GM, but after some seat time in the '06 Duramax, we're pleased to say that the improvements are more than noticeable.

As eternal diesel gearheads, it's our goal to make as much power and performance as possible, whether we need it or not. aFe (advanced FLOW engineering) located in Corona, California offered us the first bolt-on intake system for the '06 Duramax LBZ. Naturally, we were anxious to get our hands on it. When we opened the box, it had the appearance of every aFe kit we've installed: clean, well packaged and very cool looking.

The donor vehicle was actually loaned to us by the VP of engineering at aFe, Stuart Miyagishima. Other than an aFe exhaust system, the '06 4x4 2500HD LBZ was bone stock down to the floor mats. All of our dyno tests were post exhaust, so our baseline dyno was slightly higher than expected, but the overall improvement was right on the money.

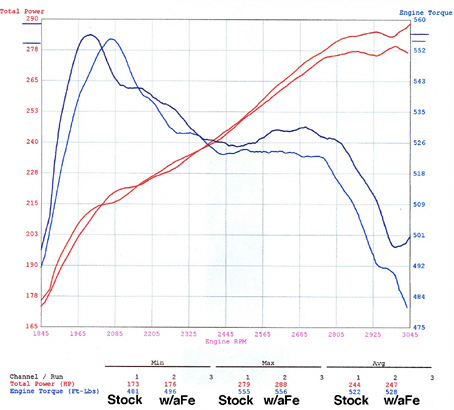

From the moment we cracked the hood open to the moment we slammed the hood was no more than 60-minutes and required only a handful of tools. The instructions were straightforward, as we would expect and everything fit like it was OE. The power on the dyno reached almost seven horsepower and 15 ft-lb. of torque. We were most impressed with the seat-of-the-pants acceleration over stock. We even noticed an improvement in throttle response! Check out the captions and dyno sheet, we think you'll be impressed!

Installation

Before starting under the hood, we assembled the heat shield to the air filter coupler.

The stock intake system had a number of odd shaped bends and couplers.

Before disassembling the stock intake path, remove the air temperature sensor.

Remove the stock intake tubing plumbing.

The stock air intake box can now be removed. It is not firmly secured, so remove it gently.

Reinstall the OE air temperature sensor into the aFe intake tube with the supplied hardware.

Next, we loosened the fender bolts beneath where the stock intake box once resided. This is where the new aFe heat shield will be located.

Using the OE fender bolts, install the aFe heat shield and Proguard-7 air filter. We made a point of installing all the bolts before tightening any of them, just in case.

We chose to install the silicone hose connectors at each end of the existing piping, before installing the rotomolded aFe tube. Given their flexibility, we figured it would make the job a little easier.

Once the last section of tubing is installed, secure all the hose clamps.

As a finishing touch, aFe included a powdercoated diamond plate cover to convert the heat shield to a complete air box.

On the dyno, the LBZ produced a tremendous torque very early. The aFe Magnum Force intake improved torque and moved the curve even further to the left, making more torque available at a lower rpm, a great improvement for towing/hauling.

Source

aFe (advanced FLOW engineering)

191 Granite St.

Corona, CA 92879

(877) 791-8811

www.afefilters.com

Back to the article index.