|

|

Most jobs are quicker, easier, & cheaper if the vehicle is CLEAN before starting. Water is safe to use on nearly everything because it's no different than driving in heavy rain. Just avoid oil seals & distributors. Some soap/surfactant (I use dilute Dawn & PurplePower) gets things even cleaner even quicker.

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

This rotor ( '80-93 MotorCraft BRR8) has been mildly scored by excessive wear on the pad ( Motorcraft BR41B). Although resurfacing or replacement is always preferred, this damage isn't severe enough to require it on a vehicle whose rotor is this difficult to remove/install. Before buying craptasmic brakes or other common parts, check for coupons & service offers from Ford.

|

|

|

Any of these could have been driving next to you.

IF THE IMAGE IS TOO SMALL, click it.

...or it could have BEEN you driving one of them.

Some of these are described in more detail in the NEXT several pics...

|

|

|

Vented Rotor - you're doing it wrong.

This is what happens when you let the brakes grind for a while. The NEXT few pics show what happens if you let it go longer.

|

|

|

Brake Rotor Wear.JPG | Hits: 8592 | Size: 88.12 KB | Posted on: 1/13/06 | Link to this image Brake Rotor Wear.JPG | Hits: 8592 | Size: 88.12 KB | Posted on: 1/13/06 | Link to this image

This rotor was allowed to wear completely through the inner surface, exposing the vent fins. The driver didn't notice until the caliper piston had hyperextended enough to leak fluid, resulting in NO pedal feel. No, it's not on a Bronco. IIRC, it was an Escort, and yes, it was a girl driving. Before buying craptasmic brakes or other common parts, check for coupons & service offers from Ford.

|

|

|

RotorVent08F450.jpg | Hits: 807 | Size: 62.88 KB | Posted on: 1/27/19 | Link to this image RotorVent08F450.jpg | Hits: 807 | Size: 62.88 KB | Posted on: 1/27/19 | Link to this image

This guy was refilling the master cylinder reservoir every morning, and didn't have brakes again every afternoon. For a month.

|

|

|

These were found on a truck that was driven to a local repair shop for "poor brake performance". The owner had let the rear pads wear away, and the inboard backing plates had eaten away the rotors until they broke off the hats - a seriously poor design by Dodge. Then he kept driving until the rotors cut into the hats again almost until another section came off. One of them DID come off when the mess was removed from the axle.

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

Driving Caliper Clips Out, rubber style (Ford F2TZ2C150A; MC BRCK5030) The stainless shells of the clip have 2 catches at each end holding the clip to the steering knuckle. Use a hammer & drift to knock the outboard catches inside the groove so the clip can be pushed through. The inner pad anti-rattle clip is D6TZ2B164C. ACDelco set of 6 clips-------------------------------------------------------------------------------- TSB 98-5A-13 NEW SPECIFICATION - Silicone Brake Caliper Grease and Dielectric Compound to be used for Disc Brake Caliper Slides Publication Date: MARCH 18, 1998 FORD: 1984-1994 TEMPO 1984-1996 MUSTANG, THUNDERBIRD 1985-1996 CROWN VICTORIA, ESCORT 1986-1996 TAURUS 1989-1996 PROBE 1994-1996 ASPIRE 1995-1996 CONTOUR LINCOLN-MERCURY: 1982-1996 CONTINENTAL 1984-1994 TOPAZ 1984-1996 COUGAR 1985-1996 GRAND MARQUIS 1986-1996 SABLE, TOWN CAR 1987-1989 TRACER 1991-1994 CAPRI 1991-1996 TRACER 1993-1996 MARK VIII 1995-1996 MYSTIQUE LIGHT TRUCK: 1983-1996 RANGER 1986-1996 AEROSTAR 1990-1996 BRONCO, ECONOLINE, F SUPER DUTY, F-150-350 SERIES 1991-1996 EXPLORER 1993-1996 VILLAGER 1995-1996 WINDSTAR MEDIUM/HEAVY TRUCK: 1990-1991 C SERIES 1990-1996 F & B SERIES ISSUE: The use of petroleum-based grease as a lubricant in servicing disc brakes is no longer acceptable because it may be incompatible with the rubber material used in the disc brake system. If petroleum-based grease is used to lubricate any part of the disc brake system, it could cause rubber parts to swell if lubricant contacts the rubber material. ACTION: Refer to the following Servicing Procedures for details. DISC BRAKE SERVICING CAUTION: DO NOT USE PETROLEUM-BASED SERVICE GREASE (SUCH AS FORD DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A) TO LUBRICATE DISC BRAKE CALIPER SLIDE PINS OR RUBBER DUST BOOTS. PETROLEUM-BASED GREASE MAY CAUSE EPDM RUBBER TO SWELL. When servicing any disc brakes, lubricate necessary components by applying Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A. Refer to the appropriate Service Manual for specific service details. DRUM BRAKE SERVICING When servicing drum brakes, apply Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A to the contact points between the brake shoes and the drum backing plates for lubrication. NOTE: DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A SHOULD NO LONGER BE USED FOR DISC BRAKE CALIPER SLIDE LUBRICATION. OTHER SERVICE APPLICATIONS Existing inventory of D7AZ-19590-A may be used for all other Service Manual procedures. Once material is exhausted, all vehicle procedures specifying Disc Brake Caliper Slide Grease (D7AZ-19590-A) should use Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A). PART NUMBER : PART NAME D7AZ-19A331-A : Silicone Brake Caliper Grease And Dielectric Compound

OTHER APPLICABLE ARTICLES: NONE SUPERSEDES: 95-21-02

|

|

|

Driving Caliper Clips Out, rubber style

The stainless shells of the clip have 2 catches at each end holding the clip to the steering knuckle. Use a hammer & drift to knock the outboard catches inside the groove so the clip can be pushed through.

--------------------------------------------------------------------------------

TSB 98-5A-13 NEW SPECIFICATION - Silicone Brake Caliper Grease and Dielectric Compound to be used for Disc Brake Caliper Slides

Publication Date: MARCH 18, 1998

FORD:

1984-1994 TEMPO

1984-1996 MUSTANG, THUNDERBIRD

1985-1996 CROWN VICTORIA, ESCORT

1986-1996 TAURUS

1989-1996 PROBE

1994-1996 ASPIRE

1995-1996 CONTOUR

LINCOLN-MERCURY:

1982-1996 CONTINENTAL

1984-1994 TOPAZ

1984-1996 COUGAR

1985-1996 GRAND MARQUIS

1986-1996 SABLE, TOWN CAR

1987-1989 TRACER

1991-1994 CAPRI

1991-1996 TRACER

1993-1996 MARK VIII

1995-1996 MYSTIQUE

LIGHT TRUCK:

1983-1996 RANGER

1986-1996 AEROSTAR

1990-1996 BRONCO, ECONOLINE, F SUPER DUTY, F-150-350 SERIES

1991-1996 EXPLORER

1993-1996 VILLAGER

1995-1996 WINDSTAR

MEDIUM/HEAVY TRUCK: 1990-1991 C SERIES

1990-1996 F & B SERIES

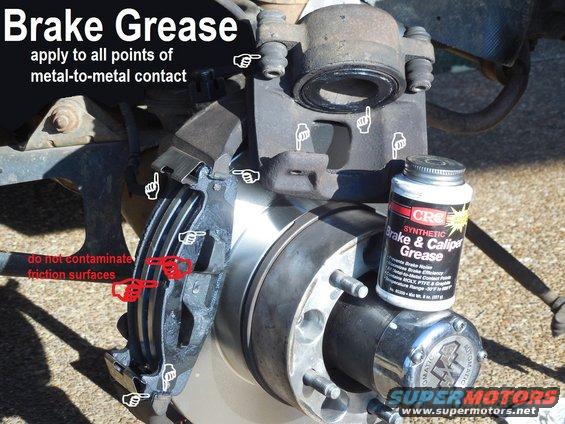

ISSUE: The use of petroleum-based grease as a lubricant in servicing disc brakes is no longer acceptable because it may be incompatible with the rubber material used in the disc brake system. If petroleum-based grease is used to lubricate any part of the disc brake system, it could cause rubber parts to swell if lubricant contacts the rubber material.

ACTION: Refer to the following Servicing Procedures for details.

DISC BRAKE SERVICING

CAUTION: DO NOT USE PETROLEUM-BASED SERVICE GREASE (SUCH AS FORD DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A) TO LUBRICATE DISC BRAKE CALIPER SLIDE PINS OR RUBBER DUST BOOTS. PETROLEUM-BASED GREASE MAY CAUSE EPDM RUBBER TO SWELL.

When servicing any disc brakes, lubricate necessary components by applying Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A. Refer to the appropriate Service Manual for specific service details.

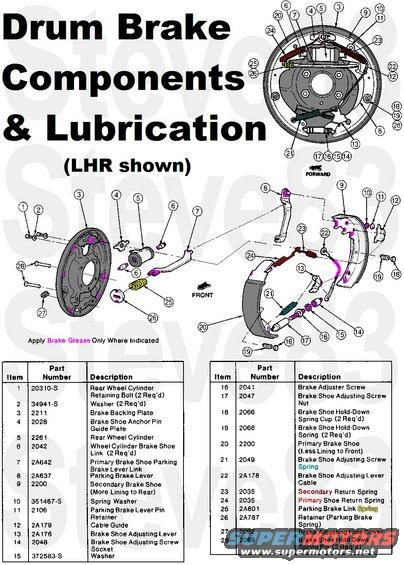

DRUM BRAKE SERVICING

When servicing drum brakes, apply Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A to the contact points between the brake shoes and the drum backing plates for lubrication.

NOTE: DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A SHOULD NO LONGER BE USED FOR DISC BRAKE CALIPER SLIDE LUBRICATION.

OTHER SERVICE APPLICATIONS

Existing inventory of D7AZ-19590-A may be used for all other Service Manual procedures. Once material is exhausted, all vehicle procedures specifying Disc Brake Caliper Slide Grease (D7AZ-19590-A) should use Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A).

PART NUMBER : PART NAME

D7AZ-19A331-A : Silicone Brake Caliper Grease And Dielectric Compound

OTHER APPLICABLE ARTICLES: NONE

SUPERSEDES: 95-21-02

|

|

|

If the rotors (BRR56 / BRR207) are heavily scored or lipped, it will be necessary to compress the caliper with a prybar before swinging the caliper & pads off the rotor. Always photograph or manually copy this style of axle tag before it becomes illegible. There is no other ID information on axles with this style of tag, so if this tag is obliterated, there's nothing left to look up parts from. Read the TSB in this caption:

|

|

|

Caliper Piston Compression Tool

Before new pads can be installed over a new rotor, the caliper must be fully compressed to make space.

If a front brake line must be opened (as for replacement), leave this step for last. Compressing the caliper will reverse-bleed the line, as long as the caliper is compressed in its normal upright position, with the brake line connection at the top.

|

|

|

Caliper Hoses

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

CaliperSlidePin.jpg | Hits: 242 | Size: 67.04 KB | Posted on: 2/17/24 | Link to this image CaliperSlidePin.jpg | Hits: 242 | Size: 67.04 KB | Posted on: 2/17/24 | Link to this image

Sliding Caliper Details

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

BrakePadsFloating.jpg | Hits: 11043 | Size: 45.43 KB | Posted on: 1/13/06 | Link to this image BrakePadsFloating.jpg | Hits: 11043 | Size: 45.43 KB | Posted on: 1/13/06 | Link to this image

Floating Caliper Pad Removal for '94-up MotorCraft Pad Set BR-46 does not include hold-down springs MotorCraft Pad Set BRF-1390 includes springs MotorCraft Pad Set BRSD-632 is super-duty pad set Wagner Semi-Metallic Pad Set MX52 [MX728A] '94-96 caliper slide bolts Motorcraft BRCK5066 (no boots) '94-96 front pads Motorcraft BR46'94-96 Front Brake Rotor Motorcraft BRR56 (BRR207?)  ____________________________________________ If you're reading this whole album for your 2WD truck, you can skip to this caption:  ____________________________________________________ TSB 98-5A-38 BRAKES - CALIPERS - FRONT CALIPER PISTON BOOTS DAMAGED Publication Date: MARCH 18, 1998 LIGHT TRUCK: 1986-91 E-250, E-350 1986-94 F-250, F-350 ISSUE: Some vehicles may have experienced deterioration of the front brake caliper piston boots resulting from exposure to high operating temperatures during severe service. ACTION: Replace the caliper piston boots with a new, more robust service caliper piston boot. The new silicone rubber boot can withstand higher operating temperatures without damage. The new boot is completely interchangeable with the prior design and will become the only service boot available. The heat damaged boots should be replaced with the new Boot (E7TZ-2207-A). Refer to the appropriate Service Manual for removal and installation procedures. PART NUMBER PART NAME E7TZ-2207-A Caliper Piston Boot OTHER APPLICABLE ARTICLES:  SUPERSEDES: 94-24-11 WARRANTY STATUS: Eligible Under The Provisions Of Bumper To Bumper Warranty Coverage For 1992-94 Model Year Vehicles, Basic Warranty Coverage For All Other Model Years OPERATION DESCRIPTION TIME 9805A38AT Overhaul Front Calipers - Both 1.5 Hrs. 9805A38A Overhaul Front Caliper - One 1.2 Hrs. --------------------------------------------------------------------------- TSB 98-5A-13 NEW SPECIFICATION - Silicone Brake Caliper Grease and Dielectric Compound to be used for Disc Brake Caliper Slides Publication Date: MARCH 18, 1998 FORD: 1984-1994 TEMPO 1984-1996 MUSTANG, THUNDERBIRD 1985-1996 CROWN VICTORIA, ESCORT 1986-1996 TAURUS 1989-1996 PROBE 1994-1996 ASPIRE 1995-1996 CONTOUR LINCOLN-MERCURY: 1982-1996 CONTINENTAL 1984-1994 TOPAZ 1984-1996 COUGAR 1985-1996 GRAND MARQUIS 1986-1996 SABLE, TOWN CAR 1987-1989 TRACER 1991-1994 CAPRI 1991-1996 TRACER 1993-1996 MARK VIII 1995-1996 MYSTIQUE LIGHT TRUCK: 1983-1996 RANGER 1986-1996 AEROSTAR 1990-1996 BRONCO, ECONOLINE, F SUPER DUTY, F-150-350 SERIES 1991-1996 EXPLORER 1993-1996 VILLAGER 1995-1996 WINDSTAR MEDIUM/HEAVY TRUCK: 1990-1991 C SERIES 1990-1996 F & B SERIES ISSUE: The use of petroleum-based grease as a lubricant in servicing disc brakes is no longer acceptable because it may be incompatible with the rubber material used in the disc brake system. If petroleum-based grease is used to lubricate any part of the disc brake system, it could cause rubber parts to swell if lubricant contacts the rubber material. ACTION: Refer to the following Servicing Procedures for details. DISC BRAKE SERVICING CAUTION: DO NOT USE PETROLEUM-BASED SERVICE GREASE (SUCH AS FORD DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A) TO LUBRICATE DISC BRAKE CALIPER SLIDE PINS OR RUBBER DUST BOOTS. PETROLEUM-BASED GREASE MAY CAUSE EPDM RUBBER TO SWELL. When servicing any disc brakes, lubricate necessary components by applying Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A. Refer to the appropriate Service Manual for specific service details. NOTE: DISC BRAKE CALIPER SLIDE GREASE D7AZ-19590-A SHOULD NO LONGER BE USED FOR DISC BRAKE CALIPER SLIDE LUBRICATION. DRUM BRAKE SERVICING When servicing drum brakes, apply Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A (Motorcraft WA-10)) or an equivalent silicone compound meeting Ford Specification ESE-M1C171-A to the contact points between the brake shoes and the drum backing plates for lubrication. OTHER SERVICE APPLICATIONS Existing inventory of D7AZ-19590-A may be used for all other Service Manual procedures. Once material is exhausted, all vehicle procedures specifying Disc Brake Caliper Slide Grease (D7AZ-19590-A) should use Silicone Brake Caliper Grease and Dielectric Compound (D7AZ-19A331-A). PART NUMBER : PART NAME D7AZ-19A331-A : Silicone Brake Caliper Grease And Dielectric Compound

OTHER APPLICABLE ARTICLES: NONE SUPERSEDES: 95-21-2  ____________________________________________ If you're reading this whole album for your 2WD truck, you can skip to this caption:

|

|

|

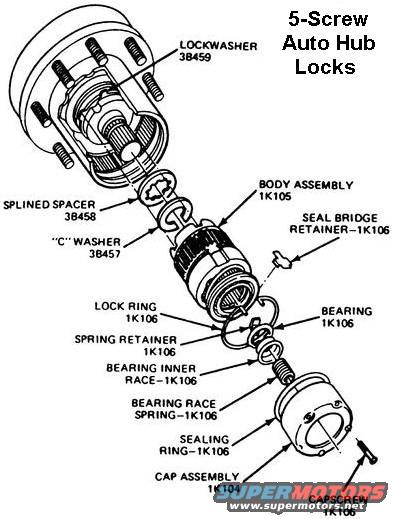

5-Screw Automatic Hub Lock Exploded IF THE IMAGE IS TOO SMALL, click it. 3B459 - E5TZ1198A There should never be a need to disassemble the hub lock body to this degree, unless it has been severely neglected or abused. DO NOT pack the lock with grease - a light coat is enough; any more will jam the mechanism. The correct way to clean & lube an auto hub lock is to dunk it in ATF each time the wheel bearings are serviced (which should be FREQUENTLY if the truck is used off-road; or every 30Kmi if it's not). The inner & outer wheel bearing adjusting nuts are not shown, but the outer (without pin) goes outboard of the perforated locking washer (3B459), which goes against the inner (with pin pointing out). If the pin is pushed into the nut, use a drift to push it back out. See also:  .  .  .  .  .

|

|

|

5-screw Lock Disassembled This level of disassembly is NOT necessary for removal or replacement. 4-slot spanner nut - E5TZ1197A 4-tab lock washer - E5TZ1198A This early axle uses a single thick steel splined thrust washer (closest to the cap screws) instead of the later 3-piece thrust washer. Install three washers in order: metal washer first, plastic washer second and splined washer last.  .  .  .  .  .  .  .

|

|

|

AutoLock5brkdn.jpg | Hits: 2786 | Size: 132.43 KB | Posted on: 3/31/15 | Link to this image AutoLock5brkdn.jpg | Hits: 2786 | Size: 132.43 KB | Posted on: 3/31/15 | Link to this image

This lock was rusty & didn't fully engage, when I was able to force it to move. So I stripped it down, soaked all the parts in kerosene for a while, and then wire-brushed each one so I could figure out how it works, and if it was repairable. Turns out there's virtually no damage under the rust & grime that I removed, so I'm putting this one in my truck. IF THE IMAGE IS TOO SMALL, click it. UPDATE 5/31/16: It has been working reliably for over a year now, including frequent off-roading, pushing trees down, and even knocking a few stumps out of the ground. Disassembly: 1) After removing the lock body assembly from the hub, wipe the grease off. Rinse in solvent (kerosene, mineral spirits, or parts cleaner) to remove as much residue as possible. 2) From the inboard end, use external snap ring pliers to expand the stator ring and push the sleeve through the body assembly. Tilt the stator assembly and lift the clutch spring tips out of the cam brake slot. 3) Remove the clutch spring cover, clutch spring, & spacer from the stator. 4) Use a pick to lift one end of the cam ring out of its groove, and work the ring out of the body. 5) Lift the cam lip opposite the brake slot, then lift the cam over the brake and out of the body. 6) Work the brake's tabs out of the body grooves, and lift out the brake. 7) Dump the sleeve assembly out of the lock body. 8 ) From the outboard end, compress the cup washer, pry out the spring ring, and remove the unlock spring from the sleeve. Remove its cup. 9) Push the stop ring out of the sleeve's groove, and remove it between the lock spring's coils. 10) Slide the sleeve out of the follower & gear. 11)Pry one of the follower's tangs over the lip of the gear, then the other, and allow the lock spring to separate them. Clean all parts thoroughly, wire-brushing as needed to remove hardened grease, dirt, & rust scale. Wash in solvent, allow to dry, then apply a thin coat of disk-brake-rated (NOT marine) wheel bearing grease using a brush or by working mating parts together. Smooth & spread the grease by hand, and remove any excess. Assembly is the reverse of disassembly, but it may be necessary to install the unlock spring last so the lock body can be held in the hub. For final lubrication & any subsequent light cleaning, submerge the lock body assembly in ATF every 30Kmi.  .  .  .  .  .  .  .

|

|

|

AutoLock5Parts.jpg | Hits: 10578 | Size: 29.46 KB | Posted on: 1/31/07 | Link to this image AutoLock5Parts.jpg | Hits: 10578 | Size: 29.46 KB | Posted on: 1/31/07 | Link to this image

These are the parts of an '80-94 5-screw Automatic Hub Lock, in the order of removal. No further disassembly of the lock body is necessary for typical maintenance - only if the lock has malfunctioned. For wheel bearing maintenance, simply dunk the lock body in ATF.  .  .  .  .  .  .

|

|

|

AutoLock5Screw.jpg | Hits: 15515 | Size: 41.35 KB | Posted on: 1/14/05 | Link to this image AutoLock5Screw.jpg | Hits: 15515 | Size: 41.35 KB | Posted on: 1/14/05 | Link to this image

5-Screw Auto Hub Lock These use a single thick splined shim between the C-clip & the spindle to hold the axle stub in place. Later designs used 3 washers. Install three washers in order: metal washer first, plastic washer second and splined washer last. Before the C-washer can be installed, the stub shaft must be pushed fully outboard against the inner spindle seal by reaching behind the steering knuckle to the u-joint. 4-slot spanner nut - E5TZ1197A 4-tab lock washer - E5TZ1198A  .  .  .  .  .  .

|

|

|

This greasy, dirty dust cap soaked in kerosene for about an hour, and then was nylon-brushed to get as clean as it is on the Left. A few seconds with some fine steel wool produced the result on the Right. It's equally-effective on bumpers, door handles, lock cylinders, antennae, and almost any other chrome or polished stainless (not bare Aluminum) surface. Stainless steel wool is preferred because common steel wool can cause rust-staining later.

|

|

|

SealBridgeClip.JPG | Hits: 4631 | Size: 92.59 KB | Posted on: 8/10/11 | Link to this image SealBridgeClip.JPG | Hits: 4631 | Size: 92.59 KB | Posted on: 8/10/11 | Link to this image

This tiny "seal bridge" clip holds the flat rubber seal up between the cap & hub. It's often discarded or lost by careless mechanics & owners, creating a leak path that contaminates the hub, making them THINK there's some mystical design fault in the auto lock when the blame really goes to the monkey with the wrench.  .  .  .  .  .  .

|

|

|

After removing the bridge clip, compress the lock body retaining ring on 5-screw auto lock, then remove the lock body & the ring together. If the lock body wiggles, but won't slide out of the hub, it may be that the hub snout is deformed (from collision or a previous grease-monkey with a BFH). It may help to spin the hub/rotor (caliper & pads removed) fast enough to locate the eccentricities of the snout, and gently hammer it back into shape to allow the lock body to slide out. This condition is much more common with early & aftermarket manual hub locks than with autos because autos fill the snout better, providing structural rigidity.  .  .  .  .  .

|

|

|

95Float5screwNuts.JPG | Hits: 4786 | Size: 85.98 KB | Posted on: 8/10/11 | Link to this image 95Float5screwNuts.JPG | Hits: 4786 | Size: 85.98 KB | Posted on: 8/10/11 | Link to this image

This '95 Bronco XLT has floating calipers with 5-screw auto hub locks and early-style wheel bearing nuts. '80-93 Front Rotor MotorCraft BRR8'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56On '87-early '88 with factory (flange-style) manual hub locks, the hub-rotor is one piece (MotorCraft BRR215?). Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96) See also:  .  .  .  .  .

|

|

|

The hub locks & their dust caps (including the dials for manual locks) do not support any weight or retain any parts. They can be R&I'ed with the truck's full weight on the wheel.

If necessary, the truck can be driven this way indefinitely, but dust & water will contaminate the wheel bearing grease if it's not taped up, or covered with plastic & a rubber band. Consider braking temperatures when choosing materials.

|

|

|

HubAutoLocks5scr.JPG | Hits: 5078 | Size: 47.75 KB | Posted on: 1/25/06 | Link to this image HubAutoLocks5scr.JPG | Hits: 5078 | Size: 47.75 KB | Posted on: 1/25/06 | Link to this image

SOLD Auto Hub Locks 5-screw

They need to be cleaned & lubed, but they're working & complete EXCEPT for the "seal bridges". Look at this diagram to see them. They can be fabricated in a few minutes with tin snips & pliers.

.  .  .  .  .

|

|

|

5-Screw Automatic Hub Locks The 3 parts labelled 3B458 are the shim washers. The outer is splined steel; the middle is fiber/plastic; the inner is smooth steel. Install three washers in order: metal washer first, plastic washer second and splined washer last. They bear the stub shaft's thrust load (caused by the C-ring), and keep it fully OUTboard so the U-joint stays aligned between the ball joints, and so the outboard small snap ring used on manual hub locks can be installed. Early axles had a single solid steel splined spacer instead of these 3.  .  .  '80-93 Front Rotor MotorCraft BRR8'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56 .  .  .  .  .

|

|

|

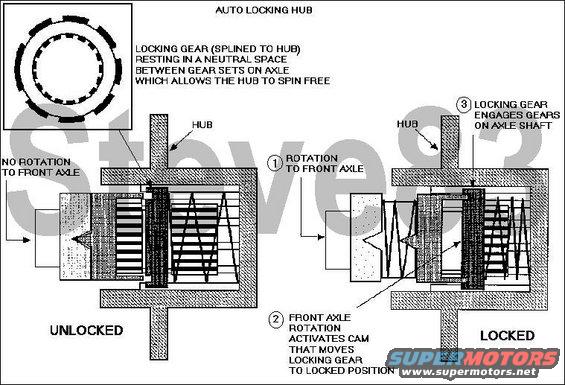

AutoHubLocksOp.jpg | Hits: 11270 | Size: 62.14 KB | Posted on: 1/1/07 | Link to this image AutoHubLocksOp.jpg | Hits: 11270 | Size: 62.14 KB | Posted on: 1/1/07 | Link to this image

Early 5-screw auto hub lock operation.  .  .  .  .  Locking and Unlocking Hubs -------------------------------------- Manual Locking Hubs Manual locking hubs are simple to diagnose. Place the transfer case in two-wheel drive and raise the front wheels off the ground. When in the unlocked position, the wheels should be able to turn freely. Then lock each of the front hubs and rotate the front wheels. The additional load of the drivetrain components should be felt once the hub has been engaged. In addition, the axle and front driveshaft should be moving along with the wheel. Disengage the hubs and repeat the procedure to check that the hubs have smoothly disengaged. Automatic Locking Hubs NOTE: While the vehicle is hoisted, shift into 4WD from a dead stop and not while rear wheels are rotating in order to avoid slamming the hub locks into the lock position. Raise vehicle on a hoist so that all wheels are off the ground. Start engine (6007) with vehicle in neutral and transfer case in 2WD. Front wheels should spin freely by hand. Put transfer case in 4WD and put vehicle in gear. Front and rear wheels should rotate together. Put vehicle in neutral and spin front wheels by hand in the forward direction. The front axle and front driveshaft should rotate with the wheels. The additional load of the drivetrain components should be felt once the hub has been engaged. To disengage the hubs, spin the wheels in the opposite direction until an audible "click" is heard. Spin wheels forward again and they should rotate freely without the axle and driveshaft rotating. Repeat the procedure, only shift into 4WD and put the vehicle in reverse. This time the hubs should release when the front wheels are spun in the forward direction. When checking front hubs for proper operation, road test the vehicle to make sure the hubs will remain engaged while under load. This is accomplished by engaging four-wheel drive and taking the vehicle through several turns (both forward and backward) on dry pavement. This will put an additional load on the front wheel at the outside of the turn because it is traveling the greatest distance. Driving through several turns while traveling in different directions will ensure that both sides of the hub teeth have been tested under load. Hubs that are not sufficiently engaged will "pop" out when loaded. This is due to the driveline releasing windup and is an indication of hub malfunction. If slippage is suspected, mark the tire and axle with chalk (after locking the hub) and apply a heavy torque load several times. Then inspect your original indexing marks. If they are no longer aligned, the hubs are not remaining locked when under load. They will have to be replaced. Should hub locks become submerged in water or mud for a long period of time, water may get past the seals and into the hubs and axle. In this case, all water must be expelled from the system. The axle must be drained by loosening the axle cover and new lubricant FITZ-19580-A (WSL-M2C191-A) used to refill the axle (FITZ-19580-A has no equivalent). Disassemble the hubs using procedures in this section and repack the wheel bearings using procedures in this section and dry off the hub locks.

|

|

|

3-screw Warn Automatic Hub Locks ( F6TZ-1K105-AA) Use a sharp pick to remove lock body retaining ring by finding the ends, then pulling one end up & out. All hub locks (3-screw, 5-screw, OE manual, & aftermarket) have a retaining ring in this location. See the NEXT photo...

|

|

|

3-screw Warn Automatic Hub Locks ( F6TZ-1K105-AA) The 2 items at the far L are one complete hub lock assembly piled together. The top center is the hub lock body. Bottom center is the cap with 3 screw holes. Top R are the friction ring & large (outer) C-ring (which retains the lock body in the hub). Lower R (upper row) are: the 2.5-inch single wheel bearing adjusting hex-nut; the adjusting nut lock clip; the steel splined thrust washer; (lower row) the small (inner) C-ring (which retains the axle stub shaft in the spindle); the plastic thrust washer; and the steel thrust washer. Refer to this:  There should never be a need to disassemble the hub lock body any more than this, unless it has been severely neglected or abused. DO NOT pack the lock with grease - a light coat is enough; any more will jam the mechanism. The correct way to clean & lube an auto hub lock is to dunk it in ATF each time the wheel bearings are serviced (which should be FREQUENTLY if the truck is used off-road; or every 30Kmi if it's not). See the NEXT pic, and:

|

|

|

AutoHubLockFail.jpg | Hits: 545 | Size: 83.69 KB | Posted on: 1/29/22 | Link to this image AutoHubLockFail.jpg | Hits: 545 | Size: 83.69 KB | Posted on: 1/29/22 | Link to this image

Auto Hub Locks SUCK!!! . . . . ...right?

IF THE IMAGE IS TOO SMALL, click it.

As bad as this looks, and despite the fact that it isn't working at the moment, there's nothing wrong with this 3-screw auto hub lock that can't be fixed with cleaning. And considering that this much water got past the 3 screws & wide O-ring of this cap, even more would have gotten in through the 5~6 screws, thin cap O-ring, and knob O-ring of a manual lock. It would also have done more rust-damage to those thinner springs. So manual hub locks are more-sensitive to neglect than autos. The only reason they seem to last longer is that they tend to be installed on trucks that need more hub maintenance anyway, so manuals get serviced more. But manual hub locks CAN & DO fail like this, and in even-worse ways.

After cleaning, this lock works perfectly. If it had been serviced the way Warn (the manufacturer) & Ford recommend (dunking in ATF twice a year), it never would have gotten this bad.

|

|

|

This lock was grimy, so I stripped it down (which required filing away some staked metal), soaked all the parts in naphtha for a while, and then scrub-brushed each one so I could figure out how it works, and if it was repairable. Turns out there's virtually no damage under the grime that I removed, like nearly all other 3-screw autos I've collected.

IF THE IMAGE IS TOO SMALL, click it.

Disassembly:

1) After removing the lock body assembly from the hub, wipe the grease off. Rinse in solvent (naphtha, kerosene, mineral spirits, or parts cleaner) to remove as much residue as possible.

2) Remove the cam assembly from the hub; wipe & rinse it similarly.

3) Rotate the ramp until its slots align with the step so it comes out.

4) Gently compress the garter, extract it from the step, and separate the garter spring so all the cam pieces can be washed in solvent & scrubbed. FURTHER DISASSEMBLY IS NOT RECOMMENDED.

5) While submerged in solvent, rotate the drive spline & follower in the body until they align so the follower can be compressed against the wave springs, flushing solvent out of & into the lock body assembly until it flows out relatively clean.

Clean all parts thoroughly, scrub-brushing as needed to remove hardened grease, dirt, & rust scale. Wash in solvent, allow to dry, then apply a thin coat of disk-brake-rated (NOT marine) wheel bearing grease using a brush or by working mating parts together. Smooth & spread the grease by hand, and remove any excess. For final lubrication & any subsequent light cleaning, submerge the lock body assembly in ATF every 30Kmi.

.  .  .  .  .  .

|

|

|

Wheel bearing adjusting nut (2.5-inch rounded hex) for 3-screw auto hub locks only. This nut requires so little torque to install that it can usually be removed with a screwdriver by hand. But the locking clip that slips into the inner grooves in the threads MUST be removed first. This is the INBOARD surface of the nut, which faces the wheel bearing. If a tool is needed, the correct one is a 2-1/2" rounded hex socket like PTW83244, Lisle 33160, OTC 6795, KD 3455, Mac WBS7795, Ford/Rotunda 205348, Lang 1244, OEM 25243, KTI 71924, or CTA 4180B. See the NEXT pic...

|

|

|

AutoHubLockFailed.jpg | Hits: 548 | Size: 76.52 KB | Posted on: 1/29/22 | Link to this image AutoHubLockFailed.jpg | Hits: 548 | Size: 76.52 KB | Posted on: 1/29/22 | Link to this image

This is the only pair of auto hub locks I've ever found that were actually ruined.

IF THE IMAGE IS TOO SMALL, click it.

|

|

|

'95-96 Bronco Front Disk Brake with floating calipers, 4WABS, 2-piece inner wheel seal, 3-screw auto hub locks; F150s do not have 4WABS, but are otherwise similar. '80-93 Front Rotor MotorCraft BRR8'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56'80-96 D44IFS Outer Wheel Bearing Koyo SET45'80-96 D44IFS Inner Wheel Bearing Timken SET36'95-96 Front Inner Wheel Seal Timken 710430'80-96 Spindle Seal Set Spicer 706527X1 - Steering Knuckle - 3130(RH) 3131(LH) 2 - Front Disc Brake Rotor Shield - 2K004 3 - Seal, Spindle Inner - 1175 or 3299 4 - Bearing, Spindle - 3123 install with writing facing outward (inboard) 5 - Spindle - 3105 6 - Nut - 35704 tighten to 47 N-m (35 lb-ft) 7 - Seal, Rolling Diaphragm, Spindle Outer - 3254 8 - Seal, Inner Wheel - 1190 9 - Bearing, Inner Wheel - 4221 or 1201 10 - Race, Inner Wheel Bearing - 4222 11 - Hub, 4WD - 1104 (part of 1102) 12 - Race, Outer Wheel Bearing - 4222 13 - Bearing, Outer Wheel - 4221 or 1216 14 - Adjusting Nut, Wheel Bearing (2.5-inch rounded hex) - 3B459 Back off 90 degrees (1/4 turn); tighten to 1.8 N-m (16 lb-in); to align notch, tighten. 15 - Retainer Key - 3B549 16 - Thrust Washer (steel) - 3B458 17 - Thrust Washer (plastic) - 3B458 18 - Thrust Washer (splined) - 3B458 19 - C-ring - 3B457 20 - Rotor, 4WD - 1125 (part of 1102) 21 - Bolt, Wheel Hub (Lug) - 1107 22 - Brake Caliper Assembly - 2B120(RH) 2B121(LH) 23 - Bolt, Caliper Slide Pin - N807683-S60 (M8-1.25 x 65) tighten to 30-36 N-m (22-27 Lb-Ft) 24 - Spring, Brake Shoe Hold-Down - 2068 25 - Drag Cam Assembly - (part of 1K105) 26 - Lock Body Assembly - ( F6TZ-1K105-AA) 27 - C-ring - (part of 1K104) 28 - Dust Cap - 1K104 29 - Screw, Dust Cap - (part of 1K104) tighten to 4-6 N-m (35-53 Lb-In) 30 - Sensor, 4WABS Front - 2L373 or 2C204 ('93-96 Bronco only) Standard ALS18531 - Screw, 4WABS Sensor - tighten to 4.5-6.8 N-m (40-60 lb-in) ('93-96 Bronco only) 32 - Shield, 4WABS Sensor - RH 4432D, LH ('93-96 Bronco only) 33 - Screw,4WABS Sensor Shield (12-point 6mm head) - ('93-96 Bronco only) 34 - 55-Tooth Speed Sensor Ring (Indicator),4WABS Front - E7TZ2B409B/F37A-2C182-AC ('93-96 Bronco only) See the NEXT pic...

|

|

|

HubLockAuto95up.jpg | Hits: 17508 | Size: 71.88 KB | Posted on: 1/2/06 | Link to this image HubLockAuto95up.jpg | Hits: 17508 | Size: 71.88 KB | Posted on: 1/2/06 | Link to this image

3-screw Warn Automatic Hub Locks ( F6TZ-1K105-AA) Regarding part #3: I think the double-lip faces INboard (toward the diff) so that if pressure is higher OUTside the hub (deep water), the double-lip will expand slightly, forming a tighter seal against the axleshaft & spindle bearing race. But that's just a guess. Before the small outboard snap ring (18 in this diagram) can be installed, the stub shaft must be pushed fully outboard against the inner spindle seal by reaching behind the steering knuckle to the u-joint.

|

|

|

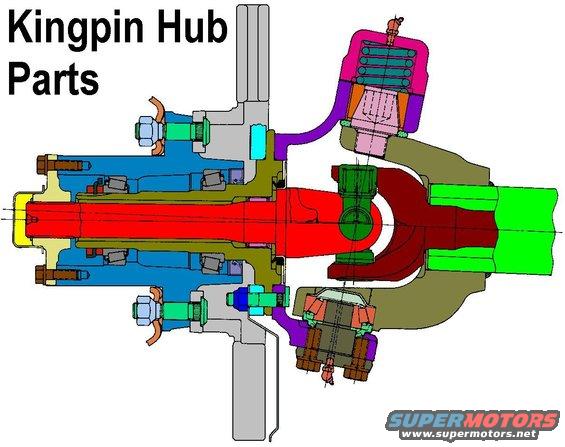

Ball Joint & Manual Hub Lock Parts IF THE IMAGE IS TOO SMALL, click it. This diagram shows a common manual hub lock. Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96) Note that, to make the drawing easier, the axle tube (bright green) is shown inclined. But in actuality, it is perfectly horizontal, and the spindle (olive green) & outer stub shaft (red) are angled slightly down. The axis of the ball joints (through the centers of the balls; not necessarily along their shafts) must pass through the center of the U-joint whenever the U-joint is rotating. That's why the location of the outer stub shaft (red) is critical, and the snap ring must be installed outboard of the spindle. Left-to-Right: Charcoal - lock knob & cam Yellow - dust cap Teal Green - dust cap screws Light Blue - engage spring Denim Blue - hub Purple - dust cap O-ring Red - outer stub shaft Green - axle snap ring Light Gray - hub lock body Black - hub lock Bright Green - outer snap ring for hub lock body Forest Green - disengage spring Olive Green - spindle Blood Red - wheel bearing adjusting nuts Charcoal - adjusting nut lock ring Pink - lock ring pin Dark Gray - wheel bearings Bright Green - lug studs Light Blue - lug nuts Orange - rim Light Gray - brake rotor (disk) Pale Purple - inner wheel seal Bright Green - spindle studs Royal Blue - spindle nuts Pink - spindle bearing [install with writing facing outward (inboard)] White - brake shield Black - inner spindle seal (early National 8430S or CR 21158; revised Spicer 706527X) Yellow - axle shim Dark Gray - axle spacer Purple - steering knuckle Pale Yellow - axle slinger Baby Blue - lower ball joint cup Dark Blue - ball joint snap rings Teal Green - axle housing Black - ball joint boots Brown - lower ball joint stud Orange - lower ball joint nut Rust Brown - inner axle stub Forest Green - universal joint caps & snap rings Pink - u-joint trunnion & seals Denim Blue - u-joint needle bearings Pale Green - upper ball joint cup Pink - upper ball joint stud Orange - camber cam Light Blue - upper ball joint castellated nut Black - upper ball joint cotter pin Lime Green - axle tube See also:  .

|

|

|

HubParts Kingpin.JPG | Hits: 7672 | Size: 49.28 KB | Posted on: 8/22/09 | Link to this image HubParts Kingpin.JPG | Hits: 7672 | Size: 49.28 KB | Posted on: 8/22/09 | Link to this image

Kingpin Hub Parts This diagram shows a drive flange (pale yellow) where most have a hub lock. Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96) Note that, to make the drawing easier, the axle tube (bright green) is shown inclined. But in actuality, it is perfectly horizontal, and the spindle (olive green) & stub shaft (red) are angled slightly down. See also:  .

|

|

|

You don't have to spend $130/pr on Warn Premium hub locks to get a lifetime warranty. And the Warns are no stronger than MileMarkers. ***SEE BELOW*** I've put ~100Kmi on these off-roading in mud/sand/rocks, and even towing another truck on the highway in FWD when my rear d'shaft was out. The only reason I changed them out today was that the knobs were starting to wear out. Hub locks (other than '87-88 flange-style) can be changed with the front wheels on the ground as normal, and the truck is even safe to drive with the locks removed, but the wheel bearings will lose grease & become contaminated. The big red NOTICE sticker says not to add ANY grease to the locks - just make sure the wheel bearings are lubed & adjusted properly. Packing the hub lock with grease will prevent it from working. ***After breaking 3 sets of these in quick succession, I've changed my mind about their strength. I returned these for credit, and I'm now running factory 5-screw auto locks.***  .

|

|

|

Stock (Warn) Manual Hub Locks

IF THE IMAGE IS TOO SMALL, click it.

This diagram has errors & omissions. The axle stub shaft retainer is not shown. For 1/2-ton (5-lug) trucks, the brake rotor attaches to the rear (inboard face) of the hub flange by the lug studs' splines.

Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00)

Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96)

Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96)

|

|

|

Hub Lock Outer Retaining Ring

IF THE IMAGE IS TOO SMALL, click it.

To make removal easier, bend the tips of the ring inward slightly. Don't bend them so much that they hit the hub lock, preventing their removal. Another option is to grind the tips at an angle so it's easier for a tool to get under the ring inside the groove.

|

|

|

HubLockManual95up.jpg | Hits: 13904 | Size: 73.14 KB | Posted on: 1/2/06 | Link to this image HubLockManual95up.jpg | Hits: 13904 | Size: 73.14 KB | Posted on: 1/2/06 | Link to this image

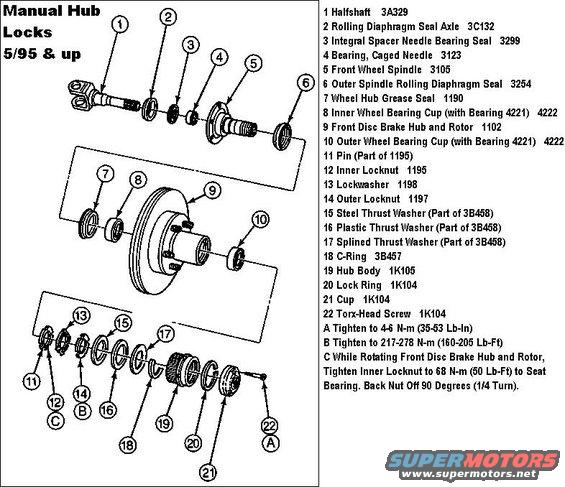

Manual Hub Locks IF THE IMAGE IS TOO SMALL, click it. These use 3 washers (15,16,17) between the C-clip & the spindle to hold the axle stub in place. The previous design used a single thick splined shim. Before that, an outside snap-ring was used at the outer end of the axle stub. In both cases, before the small outboard snap ring (18 in this diagram) can be installed, the stub shaft must be pushed fully outboard against the inner spindle seal by reaching behind the steering knuckle to the u-joint. Regarding part #2: I think the double-lip faces INboard (toward the diff) so that if pressure is higher OUTside the hub (deep water), the double-lip will expand slightly, forming a tighter seal against the axleshaft & spindle bearing race. But that's just a guess. Parts 6&7:  6 is MotorCraft BRS787 is MotorCraft BRS85'80-93 Front Rotor MotorCraft BRR8'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96)

|

|

|

FlangeHubLocks.jpg | Hits: 16053 | Size: 33.92 KB | Posted on: 1/1/07 | Link to this image FlangeHubLocks.jpg | Hits: 16053 | Size: 33.92 KB | Posted on: 1/1/07 | Link to this image

Flange-style manual hub locks used only on '87-early '88 F150s & Broncos w/manual locks. '87-88 w/auto locks are "normal". IF THE IMAGE IS TOO SMALL, click it. These are similar to those used on Bronco IIs & Explorers, but larger (5 on 5.5"). AKA "tophat" hub locks. Axles with these hub locks use special 1-piece hub/rotors, and special short spindles.  -------------------------------------------------------------------------------- TSB 88-08-17 Warn Hub Locks Inoperative Publication Date: APRIL 15, 1988 LIGHT TRUCK: 1987-88 F-150, BRONCO ISSUE: Inoperative front drive axle hublocks on 1987 and 1988 F-150 and Bronco vehicles may be caused by the control dial getting too hot and distorting. The hublock body is made of aluminum which transfers heat rapidly from the brake rotor to the hublock assembly. Under certain braking conditions such as brake dragging or downhill trailer towing control dial distortion may occur. Vehicles operated under these or similar conditions may not experience hublock control dial distortion but may be too hot for customers to engage or disengage the locking hub feature. ACTION: To correct this, install a new hublock service kit that will not allow heat transfer to the control dial. Refer to the 1987/88 Light Truck Shop Manual, Volume A, Section 11-12-2 for removal of the existing hublocks. Use the 1986 Light Truck Shop Manual to install the new hublock kit, (E7TZ-1L104-A). PART NUMBER PART NAME E7TZ-1L104-A Hublock Kit - One (1) Required OTHER APPLICABLE ARTICLES: NONE WARRANTY STATUS: Eligible Under Basic Warranty Coverage OPERATION DESCRIPTION TIME 880817A Both hubs 1.8 Hrs.

|

|

|

HubLocksFlange.JPG | Hits: 10523 | Size: 93.88 KB | Posted on: 8/23/07 | Link to this image HubLocksFlange.JPG | Hits: 10523 | Size: 93.88 KB | Posted on: 8/23/07 | Link to this image

Flange-style Hub Locks, a.k.a. TopHats

Note the LACK of screws around the selector dial.

--------------------------------------------------------------------------------

TSB 88-08-17 Warn Hub Locks Inoperative

Publication Date: APRIL 15, 1988

LIGHT TRUCK: 1987-88 F-150, BRONCO

ISSUE: Inoperative front drive axle hublocks on 1987 and 1988 F-150 and Bronco vehicles may be caused by the control dial getting too hot and distorting. The hublock body is made of aluminum which transfers heat rapidly from the brake rotor to the hublock assembly. Under certain braking conditions such as brake dragging or downhill trailer towing control dial distortion may occur. Vehicles operated under these or similar conditions may not experience hublock control dial distortion but may be too hot for customers to engage or disengage the locking hub feature.

ACTION: To correct this, install a new hublock service kit that will not allow heat transfer to the control dial. Refer to the 1987/88 Light Truck Shop Manual, Volume A, Section 11-12-2 for removal of the existing hublocks. Use the 1986 Light Truck Shop Manual to install the new hublock kit, (E7TZ-1L104-A).

PART NUMBER PART NAME

E7TZ-1L104-A Hublock Kit - One (1) Required

OTHER APPLICABLE ARTICLES: NONE

WARRANTY STATUS: Eligible Under Basic Warranty Coverage

OPERATION DESCRIPTION TIME

880817A Both hubs 1.8 Hrs.

|

|

|

HubLockSpicerMan.jpg | Hits: 10029 | Size: 27.32 KB | Posted on: 12/2/05 | Link to this image HubLockSpicerMan.jpg | Hits: 10029 | Size: 27.32 KB | Posted on: 12/2/05 | Link to this image

Early Hub Lock Exploded Diagrams IF THE IMAGE IS TOO SMALL, click it. Excerpts from the Dana/Spicer hub lock service manual. http://www2.dana.com/pdf/5330.PDF available from the Dana Axle Expert site's Librarian. http://www2.dana.com/Expert/wc.dll?DSD~demenu~DEMENUA~Before the small outboard snap ring can be installed, the stub shaft must be pushed fully outboard against the inner spindle seal by reaching behind the steering knuckle to the u-joint. See also:

|

|

|

4WABS Rotor Removal IF THE IMAGE IS TOO SMALL, click it. If the rotor must be replaced on a '93-96 Bronco (4WABS) hub, the tone ring often causes problems because it's not easy to pull with a 3-jaw puller, and replacements are not available new. But by using a simple frame (I have this steel ring, but a triangle of 2x10" lumber is just as effective) to support the rotor above a wood pad on a concrete slab, the tone ring comes off fairly easily & quickly. 1) Hammer the studs loose, but don't damage the tone ring; then free the rotor from the hub (since the rotor is being replaced, hammering the rotor face is OK; 2) Place the rotor (hub-down) onto the frame on top of the wood pad; 3) The loose hub's weight holds the tone ring against the backs of the studs, which are against the rotor, which is on the frame on the board; holding the frame & rotor together, lift them off the pad and slam them down sharply, flat onto the pad 4) The impact will pull the hub down through the tone ring; 5) A few hard hits should be enough to separate the ring from the hub; 6) All 8 pieces are loose now, but the 5 studs are resting in the rotor; 7) The rotor holes are larger, so the lug studs' splines don't engage it - they fall out easily; 8 ) The hub can now be cleaned (especially the machined surfaces that the rotor & wheel mount against) and painted (if desired). See also:  .  .  .

|

|

|

'80-96 rotor replacement requires removing the hub assembly & driving out the lug studs ( Dorman 610-219). On '93-96 Broncos only, the tone ring must be removed. '80-93 Front Rotor MotorCraft BRR8'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56'94-96 Bronco hub/rotor/tone-ring assembly Napa NB 4886441'93 Bronco hub/rotor/tone-ring assembly Napa NB 4886444On '87-early '88 with factory (flange-style) manual hub locks, the hub-rotor is one piece (MotorCraft BRR215?). Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) ( Dorman 610-219) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96) REASSEMBLY 1. Thoroughly clean the faces of the hub & rotor where they touch each other, AND where the rim will touch.  2. Set the rotor onto the back of the hub. 3. Drive the lug studs through both. 4. If applicable, install the tone ring. 5. Drop the packed inner wheel bearing (XW4Z-4221-AA) into its race in the back of the hub, & apply a ring of grease to its visible surface. 6. Install the appropriate inner wheel seal ('80-94 C9TZ-1S175-C). 7. Flip the assembly & apply a heavy ring of grease to the area between the bearing races in the hub. 8. Slip the hub onto the spindle ('93-96 F3TZ-3105-D), keeping as much grease as possible inside. 9. Fill as much of the hub as possible with grease, up to the outer wheel bearing race. 10. Slip the packed outer bearing (DV6Z-4221-A) onto the spindle, centering the hub around it so it goes in all the way. 11. Leaving any excess grease in place, install the wheel bearing adjusting nut(s) according to the appropriate procedure. 12. Fill the area between the nut(s) & hub wall with grease, NOT to extend outboard of the nuts. 13. Install any necessary hardware & the hub locks. 14. Install the wheel, using a torque wrench or torque-limiter as described in the TSB below. Re-check torque after 200-500 miles. See also:  .

|

|

|

ToneRingRemoval.jpg | Hits: 2263 | Size: 124.21 KB | Posted on: 10/16/14 | Link to this image ToneRingRemoval.jpg | Hits: 2263 | Size: 124.21 KB | Posted on: 10/16/14 | Link to this image

Using this seal & bearing driver is one way to remove the '93-96 Bronco-only 4WABS tone ring. Another way is: after hammering the lugs out (but not so far as to damage the tone ring), drop the rotor onto a wood support tall enough to allow the hub to slide down and out of the tone ring. DO NOT allow the thin outer lip of the hub to impact any hard surface. Pad the pavement with plywood or several layers of cardboard, as this page shows:

|

|

|

Rotor Installation 1. Set the rotor onto the back of the hub. 2. Drive the lug studs ( Dorman 610-219) through both. 3. If applicable ('93-96 Bronco only), install the tone ring. 4. Drop the packed inner wheel bearing into its race in the back of the hub, & apply a ring of grease to its visible surface. 5. Install the appropriate inner wheel seal. 6. Flip the assembly & apply a heavy ring of grease to the area between the bearing races inside the hub. 7. Slip the hub onto the spindle, keeping as much grease as possible inside. 8. Fill as much of the hub as possible with grease, up to the outer wheel bearing race. 9. Slip the packed outer bearing onto the spindle, centering the hub around it so it goes in all the way. 10. Leaving any excess grease in place, install the wheel bearing adjusting nut(s) according to the appropriate procedure. 11. Fill the area between the nut(s) & hub wall with grease, NOT to extend outboard of the nuts. 12. Install any necessary hardware & the hub locks. '80-93 Front Rotor MotorCraft BRR8, hub/rotor assembly Raybestos 66439R'79-85 Front Pads Motorcraft BR43B'86-93 Front Pads Motorcraft BR41B'94-96 Front Pads Motorcraft BR46'94-96 Front Rotor Motorcraft BRR56, hub/rotor/tone-ring assembly Raybestos 66441ROn '87-early '88 with factory (flange-style) manual hub locks, the hub-rotor is one piece (MotorCraft BRR215?). Ford 8.8" axle uses 10 lug studs D6AZ-1107-A ('83-00) Dana 44IFS uses 10 lug studs D6TZ-1107-A ('83-96) Ford TIB axle uses 10 lug studs F4UZ-1107-A ('94-96)

|

|

|

Front ABS Sensors Motorcraft BRAB30 on '93-96 Broncos only. Clean all metal filings off to improve signal quality. To remove the spindle, remove the sensor bolt (6-point 8mm-5/16") and the shield bolt (12-point 6mm, but a 12-point 7/32" can be hammered onto it) from inside the steering knuckle. Once the spindle is off, drive the sensor inboard HAMMERING ONLY on the tube around the bolt. Clean both sensor bores thoroughly with a steel bore brush, and clean the sensor & its bolt tube. Apply anti-seize lube to both bores before reinstalling the sensor, and to the spindle bore of the steering knuckle. Whether the spindle was removed or not; clean its sealing surfaces thoroughly.

|

|

|

The bolt for this shield has an extremely hard-to-find 6mm 12-point head, so most people (including me) don't carry a socket to fit it. Since I've abandoned my idea to add 4WABS TC to my truck, I didn't need the sensor or the shield, so I just knocked it off with a hammer. If I need to reinstall it, I'll use a bolt with a 6-point head.

Turns out a more-common 12-point 7/32" socket can be hammered onto this bolt head.

|

|

|

Spindle Differences '80-96 In addition to the ~'92 loss of a spindle stud (leaving 5) and the addition of 2 notches in the spindle flange for the (Bronco only) 4WABS sensor used on '93-96 Broncos only, the spindle was also redesigned in ~'95 to match the revised 2-piece inner wheel seal. F150 spindle flanges were not notched or drilled for the 4WABS sensor, but are otherwise identical to the corresponding Bronco's. I suspect the slot was lengthened around '86 for the self-locking spindle nut, but I haven't confirmed that. '87-early '88 spindles for manual (top-hat flange-style) hub locks are significantly shorter overall, take a 1-piece hub/rotor, and have 6 stud holes. To remove stuck spindles with a slide hammer, use Sunex 10208, Lisle 22200, KD 3910, or OTC 4543-6 or 7502. To prevent them from sticking again, clean ALL the rust from the bores & stickouts, and apply anti-seize lube. Early D-head 3/8" Spicer 363261 spindle stud (6 per spindle) and Spicer 357041 3/8" nut. See also:  .  .  .  .  .  D44IFS Bills of Material (Dana Part Numbers): 610062-1 Standard 3.00 80 1/2-ton 610062-2 Standard 3.00 80 1/2-ton 610062-3 Standard 3.50 80 1/2-ton 610062-4 Standard 3.50 80 1/2-ton 610062-5 Trac Lok 3.50 80 1/2-ton 610062-6 Trac Lok 3.50 80 1/2-ton 610062-7 Standard 3.00 80 1/2-ton 610062-8 Standard 3.00 80 1/2-ton 610062-9 Standard 3.50 80 1/2-ton 610062-10 Standard 3.50 80 1/2-ton 610062-11 Trac Lok 3.50 80 1/2-ton 610062-12 Trac Lok 3.50 80 1/2-ton 610062-13 Standard 3.00 80 1/2-ton 610062-14 Standard 3.00 80 1/2-ton 610062-15 Standard 3.50 80 1/2-ton 610062-16 Standard 3.50 80 1/2-ton 610062-17 Trac Lok 3.50 80 1/2-ton 610062-18 Trac Lok 3.50 80 1/2-ton 610062-19 Standard 3.00 80 1/2-ton 610063-1 Standard 3.54 80 3/4-ton 610063-2 Standard 3.54 80 3/4-ton 610063-3 Trac Lok 3.54 80 3/4-ton 610063-4 Trac Lok 3.54 80 3/4-ton 610063-5 Standard 4.09 80 3/4-ton 610063-6 Standard 3.54 80 3/4-ton 610146-1 Standard 3.00 81 3/4 & 1-ton 610146-2 Trac Lok 3.00 81 3/4 & 1-ton 610146-3 Standard 3.54 81 3/4 & 1-ton 610146-4 Trac Lok 3.54 81 3/4 & 1-ton 610146-5 Standard 3.00 81 3/4 & 1-ton 610146-6 Standard 3.54 81 3/4 & 1-ton 610146-7 Standard 3.54 81 3/4 & 1-ton 610146-8 Standard 4.09 81 3/4 & 1-ton 610146-9 Trac Lok 3.54 81 3/4 & 1-ton 610185-1 Standard 3.00 81 & 82 1/2-ton 610185-2 Standard 3.00 81 & 82 1/2-ton 610185-3 Standard 3.50 81 & 82 1/2-ton 610185-4 Standard 3.50 81 & 82 1/2-ton 610185-5 Trac Lok 3.50 81 & 82 1/2-ton 610185-6 Trac Lok 3.50 81 & 82 1/2-ton 610185-7 Standard 3.50 81 & 82 1/2-ton 610185-8 Standard 3.00 81 & 82 1/2-ton 610185-9 Standard 3.00 81 & 82 1/2-ton 610185-10 Standard 3.50 81 & 82 1/2-ton 610185-11 Standard 3.50 81 & 82 1/2-ton 610185-12 Trac Lok 3.50 81 & 82 1/2-ton 610185-13 Standard 3.50 81 & 82 1/2-ton 610185-14 Standard 3.07 81 & 82 1/2-ton 610185-15 Standard 3.07 81 & 82 1/2-ton 610185-16 Trac Lok 3.54 81 & 82 1/2-ton 610185-17 Standard 3.54 81 & 82 1/2-ton 610185-18 Standard 3.54 81 & 82 1/2-ton 610166-1 Standard 3.50 81.5 & 82 F150 SnowPlow 610166-2 Standard 3.50 81.5 & 82 F150 SnowPlow 610166-3 Trac Lok 3.00 81.5 & 82 F150 SnowPlow 610168-1 Standard 3.00 83 1/2-ton 610168-2 Standard 3.50 83 1/2-ton 610168-3 Trac Lok 3.50 83 1/2-ton 610168-4 Standard 3.00 83 1/2-ton 610168-5 Standard 3.00 83 1/2-ton 610168-6 Standard 3.50 83 1/2-ton 610168-7 Standard 3.50 83 1/2-ton 610168-8 Trac Lok 3.50 83 1/2-ton 610168-9 Standard 3.07 83 1/2-ton 610168-10 Standard 3.07 83 1/2-ton 610168-11 Trac Lok 3.54 83 1/2-ton 610168-12 Standard 3.54 83 1/2-ton 610168-13 Standard 3.54 83 1/2-ton 610167-2 Standard 3.50 83 F150 SnowPlow 610167-4 Standard 3.54 83 F150 SnowPlow 610169-1 Standard 3.00 83 3/4 & 1-ton 610169-2 Standard 3.54 83 3/4 & 1-ton 610169-3 Standard 3.00 83 3/4 & 1-ton 610169-4 Standard 3.54 83 3/4 & 1-ton 610169-5 Standard 3.54 83 3/4 & 1-ton 610169-6 Standard 4.09 83 3/4 & 1-ton 610169-7 Trac Lok 3.54 83 3/4 & 1-ton 610178-1 Standard 3.07 84 1/2-ton 610178-2 Standard 3.07 84 1/2-ton 610178-3 Trac Lok 3.54 84 1/2-ton 610178-4 Standard 3.54 84 1/2-ton 610178-5 Standard 3.54 84 1/2-ton 610178-9 Standard 3.07 84 1/2-ton 610178-10 Standard 3.07 84 1/2-ton 610178-11 Trac Lok 3.54 84 1/2-ton 610178-12 Trac Lok 3.54 84 1/2-ton 610178-13 Trac Lok 3.54 84 1/2-ton 610177-1 Standard 3.54 84 F150 SnowPlow 610177-4 Standard 3.54 84 F150 SnowPlow 610179-1 Standard 3.54 84 3/4 & 1-ton 610179-2 Standard 3.54 84 3/4 & 1-ton 610179-3 Standard 3.54 84 3/4 & 1-ton 610179-4 Standard 3.54 84 3/4 & 1-ton 610179-5 Standard 3.54 84 3/4 & 1-ton 610179-6 Standard 4.09 84 3/4 & 1-ton 610179-7 Trac Lok 3.54 84 3/4 & 1-ton 610179-8 Trac Lok 3.54 84 3/4 & 1-ton 610198-1 Standard 3.07 84.5 & 85 1/2-ton 610198-2 Standard 3.07 84.5 & 85 1/2-ton 610198-3 Trac Lok 3.54 84.5 & 85 1/2-ton 610198-4 Standard 3.54 84.5 & 85 1/2-ton 610198-5 Standard 3.54 84.5 & 85 1/2-ton 610198-9 Standard 3.07 84.5 & 85 1/2-ton 610198-10 Standard 3.07 84.5 & 85 1/2-ton 610198-11 Trac Lok 3.54 84.5 & 85 1/2-ton 610198-12 Standard 3.54 84.5 & 85 1/2-ton 610198-13 Standard 3.54 84.5 & 85 1/2-ton 610198-14 Standard 3.50 84.5 & 85 1/2-ton 610198-15 Standard 3.50 84.5 & 85 1/2-ton 610198-16 Trac Lok 3.50 84.5 & 85 1/2-ton 610198-17 Standard 4.09 84.5 & 85 1/2-ton 610198-18 Trac Lok 4.09 84.5 & 85 1/2-ton 610197-1 Standard 3.54 84.5 & 85 F150 SnowPlow 610197-4 Standard 3.54 84.5 & 85 F150 SnowPlow 610197-5 Standard 3.50 84.5 & 85 F150 SnowPlow 610199-1 Standard 3.54 84.5 & 85 3/4-ton 610199-2 Standard 3.54 84.5 & 85 3/4-ton 610199-3 Standard 3.54 84.5 & 85 3/4-ton 610199-4 Standard 3.54 84.5 & 85 3/4-ton 610199-5 Standard 3.54 84.5 & 85 3/4-ton 610199-6 Standard 4.09 84.5 & 85 3/4-ton 610199-7 Trac Lok 3.54 84.5 & 85 3/4-ton 610199-8 Standard 4.09 84.5 & 85 3/4-ton 610199-9 Trac Lok 4.09 84.5 & 85 3/4-ton 610199-10 Trac Lok 4.09 84.5 & 85 3/4-ton 610229-1 Standard 3.54 85 3/4-ton 610229-2 Standard 3.54 85 3/4-ton 610229-3 Standard 3.54 85 3/4-ton 610229-4 Trac Lok 3.54 85 3/4-ton 610229-5 Standard 4.09 85 3/4-ton 610229-6 Trac Lok 4.09 85 3/4-ton 610231-1 Standard 3.54 85 3/4 & 1-ton 610231-2 Standard 3.54 85 3/4 & 1-ton 610231-3 Standard 4.09 85 3/4 & 1-ton 610231-4 Trac Lok 3.54 85 3/4 & 1-ton 610231-5 Standard 4.09 85 3/4 & 1-ton 610231-6 Trac Lok 4.09 85 3/4 & 1-ton 610241-1 Standard 3.07 85.5 1/2-ton 610241-2 Trac Lok 3.54 85.5 1/2-ton 610241-3 Standard 3.54 85.5 1/2-ton 610241-4 Standard 3.50 85.5 1/2-ton 610241-5 Trac Lok 3.50 85.5 1/2-ton 610241-6 Standard 4.09 85.5 1/2-ton 610241-7 Trac Lok 4.09 85.5 1/2-ton 610242-1 Standard 3.54 85.5 F150 SnowPlow 610242-2 Standard 3.50 85.5 F150 SnowPlow 610243-1 Standard 3.54 88.5 3/4-ton 610243-2 Standard 3.54 88.5 3/4-ton 610243-3 Standard 4.09 88.5 3/4-ton 610243-4 Trac Lok 3.54 88.5 3/4-ton 610243-5 Standard 4.09 88.5 3/4-ton 610243-6 Trac Lok 4.09 88.5 3/4-ton 610261-1 Standard 3.07 86 1/2-ton 610261-2 Standard 3.54 86 1/2-ton 610261-3 Standard 3.50 86 1/2-ton 610262-1 Standard 3.07 86 1/2-ton 610262-2 Trac Lok 3.54 86 1/2-ton 610262-3 Standard 3.54 86 1/2-ton 610262-4 Standard 3.50 86 1/2-ton 610262-5 Trac Lok 3.50 86 1/2-ton 610262-6 Standard 4.09 86 1/2-ton 610262-7 Trac Lok 4.09 86 1/2-ton 610263-1 Standard 3.54 86 F150 SnowPlow 610263-2 Standard 3.50 86 F150 SnowPlow 610264-1 Standard 3.54 86 & 87 3/4-ton 610264-2 Standard 3.54 86 & 87 3/4-ton 610264-3 Standard 4.09 86 & 87 3/4-ton 610264-4 Trac Lok 3.54 86 & 87 3/4-ton 610264-5 Standard 4.09 86 & 87 3/4-ton 610264-6 Trac Lok 4.09 86 & 87 3/4-ton 610267-1 Standard 3.07 87 & 88 1/2-ton 610267-2 Trac Lok 3.54 87 & 88 1/2-ton 610267-3 Standard 3.54 87 & 88 1/2-ton 610267-4 Standard 3.50 87 & 88 1/2-ton 610267-6 Standard 4.09 87 & 88 1/2-ton 610268-1 Standard 3.07 87 & 88 1/2-ton 610268-2 Standard 3.54 87 & 88 1/2-ton 610266-1 Standard 3.54 87 & 88 SnowPlow 610266-2 Standard 3.50 87 & 88 SnowPlow 610306-1 Standard 3.54 88 3/4-ton 610306-2 Standard 4.09 88 3/4-ton 610309-1 Standard 3.07 88.5 F150 SnowPlow 610309-2 Trac Lok 3.54 88.5 F150 SnowPlow 610309-3 Standard 3.54 88.5 F150 SnowPlow 610309-4 Standard 4.09 88.5 F150 SnowPlow 610311-1 Standard 3.54 88.5 - 91 1/2-ton 610311-2 Standard 4.09 88.5 - 91 1/2-ton 610310-1 Standard 3.07 88.5 - 92 1/2-ton 610310-2 Standard 3.54 88.5 - 92 1/2-ton 610335-1 Standard 3.07 88.5 - 92 1/2-ton 610335-2 Trac Lok 3.54 88.5 - 92 1/2-ton 610335-3 Standard 3.54 88.5 - 92 1/2-ton 610335-4 Standard 4.09 88.5 - 92 1/2-ton 610407-1 Standard 3.07 92.5 1/2-ton 610407-3 Standard 3.54 92.5 1/2-ton 610408-1 Standard 3.07 92.5 1/2-ton 610408-3 Standard 3.54 92.5 1/2-ton 610408-4 Standard 4.09 92.5 1/2-ton 610408-6 Trac Lok 3.54 92.5 1/2-ton 610408-7 Standard 3.07 92.5 1/2-ton 610408-9 Standard 3.54 92.5 1/2-ton 610411-1 Standard 3.07 93 & 93.5 Bronco 610411-2 Trac Lok 3.54 93 & 93.5 Bronco 610411-3 Standard 3.54 93 & 93.5 Bronco 610411-4 Standard 4.09 93 & 93.5 Bronco 610411-7 Standard 3.07 93 & 93.5 Bronco 610411-8 Standard 3.54 93 & 93.5 Bronco 610414-1 Standard 3.07 93 & 93.5 F150 610414-3 Standard 3.54 93 & 93.5 F150 610414-4 Standard 4.09 93 & 93.5 F150 610414-6 Trac Lok 3.54 93 & 93.5 F150 610414-7 Standard 3.07 93 & 93.5 F150 610414-9 Standard 3.54 93 & 93.5 F150 610443-3 Standard 3.54 94 - 96 Bronco 610443-9 Standard 3.54 94 - 96 Bronco 610447-3 Standard 3.54 94 - 96 Bronco 610447-9 Standard 3.54 94 - 96 Bronco 610447-10 Standard 3.54 94 - 96 Bronco 610444-1 Standard 3.07 94 F150 610444-2 Standard 3.31 94 F150 610444-3 Standard 3.54 94 F150 610444-4 Standard 4.09 94 F150 610444-5 Trac Lok 3.31 94 F150 610444-6 Trac Lok 3.54 94 F150 610444-7 Standard 3.07 94 F150 610444-8 Standard 3.31 94 F150 610444-9 Standard 3.54 94 F150 610446-1 Standard 3.07 95 & 96 F150 610446-2 Standard 3.31 95 & 96 F150 610446-3 Standard 3.54 95 & 96 F150 610446-5 Trac Lok 3.31 95 & 96 F150 610446-6 Trac Lok 3.54 95 & 96 F150 610446-10 Standard 3.07 95 & 96 F150 610446-11 Standard 3.31 95 & 96 F150 610446-12 Standard 3.54 95 & 96 F150 610608-1 Standard 3.54 96.5 Bronco 610608-2 Standard 3.54 96.5 Bronco 610607-1 Standard 3.07 96.5 F150 610607-2 Standard 3.31 96.5 F150 610607-3 Standard 3.54 96.5 F150 610607-4 Standard 4.09 96.5 F150 610607-5 Trac Lok 3.31 96.5 F150 610607-6 Trac Lok 3.54 96.5 F150 610607-7 Standard 3.07 96.5 F150 610607-8 Standard 3.31 96.5 F150 610607-9 Standard 3.54 96.5 F150

|

|

|

KnuckleDifferences93.JPG | Hits: 6030 | Size: 45.09 KB | Posted on: 3/27/10 | Link to this image KnuckleDifferences93.JPG | Hits: 6030 | Size: 45.09 KB | Posted on: 3/27/10 | Link to this image

Differences in steering knuckles, spindles, & hubs. Both sets shown are from '93 trucks. IF THE IMAGE IS TOO SMALL, click it. See also:  .  .  .  .  .  For more detailed info, read this Dana PDF: http://www2.dana.com/pdf/X510-9.pdfD44IFS Bills of Material (Dana Part Numbers): 610062-1 Standard 3.00 80 1/2-ton 610062-2 Standard 3.00 80 1/2-ton 610062-3 Standard 3.50 80 1/2-ton 610062-4 Standard 3.50 80 1/2-ton 610062-5 Trac Lok 3.50 80 1/2-ton 610062-6 Trac Lok 3.50 80 1/2-ton 610062-7 Standard 3.00 80 1/2-ton 610062-8 Standard 3.00 80 1/2-ton 610062-9 Standard 3.50 80 1/2-ton 610062-10 Standard 3.50 80 1/2-ton 610062-11 Trac Lok 3.50 80 1/2-ton 610062-12 Trac Lok 3.50 80 1/2-ton 610062-13 Standard 3.00 80 1/2-ton 610062-14 Standard 3.00 80 1/2-ton 610062-15 Standard 3.50 80 1/2-ton 610062-16 Standard 3.50 80 1/2-ton 610062-17 Trac Lok 3.50 80 1/2-ton 610062-18 Trac Lok 3.50 80 1/2-ton 610062-19 Standard 3.00 80 1/2-ton 610063-1 Standard 3.54 80 3/4-ton 610063-2 Standard 3.54 80 3/4-ton 610063-3 Trac Lok 3.54 80 3/4-ton 610063-4 Trac Lok 3.54 80 3/4-ton 610063-5 Standard 4.09 80 3/4-ton 610063-6 Standard 3.54 80 3/4-ton 610146-1 Standard 3.00 81 3/4 & 1-ton 610146-2 Trac Lok 3.00 81 3/4 & 1-ton 610146-3 Standard 3.54 81 3/4 & 1-ton 610146-4 Trac Lok 3.54 81 3/4 & 1-ton 610146-5 Standard 3.00 81 3/4 & 1-ton 610146-6 Standard 3.54 81 3/4 & 1-ton 610146-7 Standard 3.54 81 3/4 & 1-ton 610146-8 Standard 4.09 81 3/4 & 1-ton 610146-9 Trac Lok 3.54 81 3/4 & 1-ton 610185-1 Standard 3.00 81 & 82 1/2-ton 610185-2 Standard 3.00 81 & 82 1/2-ton 610185-3 Standard 3.50 81 & 82 1/2-ton 610185-4 Standard 3.50 81 & 82 1/2-ton 610185-5 Trac Lok 3.50 81 & 82 1/2-ton 610185-6 Trac Lok 3.50 81 & 82 1/2-ton 610185-7 Standard 3.50 81 & 82 1/2-ton 610185-8 Standard 3.00 81 & 82 1/2-ton 610185-9 Standard 3.00 81 & 82 1/2-ton 610185-10 Standard 3.50 81 & 82 1/2-ton 610185-11 Standard 3.50 81 & 82 1/2-ton 610185-12 Trac Lok 3.50 81 & 82 1/2-ton 610185-13 Standard 3.50 81 & 82 1/2-ton 610185-14 Standard 3.07 81 & 82 1/2-ton 610185-15 Standard 3.07 81 & 82 1/2-ton 610185-16 Trac Lok 3.54 81 & 82 1/2-ton 610185-17 Standard 3.54 81 & 82 1/2-ton 610185-18 Standard 3.54 81 & 82 1/2-ton 610166-1 Standard 3.50 81.5 & 82 F150 SnowPlow 610166-2 Standard 3.50 81.5 & 82 F150 SnowPlow 610166-3 Trac Lok 3.00 81.5 & 82 F150 SnowPlow 610168-1 Standard 3.00 83 1/2-ton 610168-2 Standard 3.50 83 1/2-ton 610168-3 Trac Lok 3.50 83 1/2-ton 610168-4 Standard 3.00 83 1/2-ton 610168-5 Standard 3.00 83 1/2-ton 610168-6 Standard 3.50 83 1/2-ton 610168-7 Standard 3.50 83 1/2-ton 610168-8 Trac Lok 3.50 83 1/2-ton 610168-9 Standard 3.07 83 1/2-ton 610168-10 Standard 3.07 83 1/2-ton 610168-11 Trac Lok 3.54 83 1/2-ton 610168-12 Standard 3.54 83 1/2-ton 610168-13 Standard 3.54 83 1/2-ton 610167-2 Standard 3.50 83 F150 SnowPlow 610167-4 Standard 3.54 83 F150 SnowPlow 610169-1 Standard 3.00 83 3/4 & 1-ton 610169-2 Standard 3.54 83 3/4 & 1-ton 610169-3 Standard 3.00 83 3/4 & 1-ton 610169-4 Standard 3.54 83 3/4 & 1-ton 610169-5 Standard 3.54 83 3/4 & 1-ton 610169-6 Standard 4.09 83 3/4 & 1-ton 610169-7 Trac Lok 3.54 83 3/4 & 1-ton 610178-1 Standard 3.07 84 1/2-ton 610178-2 Standard 3.07 84 1/2-ton 610178-3 Trac Lok 3.54 84 1/2-ton 610178-4 Standard 3.54 84 1/2-ton 610178-5 Standard 3.54 84 1/2-ton 610178-9 Standard 3.07 84 1/2-ton 610178-10 Standard 3.07 84 1/2-ton 610178-11 Trac Lok 3.54 84 1/2-ton 610178-12 Trac Lok 3.54 84 1/2-ton 610178-13 Trac Lok 3.54 84 1/2-ton 610177-1 Standard 3.54 84 F150 SnowPlow 610177-4 Standard 3.54 84 F150 SnowPlow 610179-1 Standard 3.54 84 3/4 & 1-ton 610179-2 Standard 3.54 84 3/4 & 1-ton 610179-3 Standard 3.54 84 3/4 & 1-ton 610179-4 Standard 3.54 84 3/4 & 1-ton 610179-5 Standard 3.54 84 3/4 & 1-ton 610179-6 Standard 4.09 84 3/4 & 1-ton 610179-7 Trac Lok 3.54 84 3/4 & 1-ton 610179-8 Trac Lok 3.54 84 3/4 & 1-ton 610198-1 Standard 3.07 84.5 & 85 1/2-ton 610198-2 Standard 3.07 84.5 & 85 1/2-ton 610198-3 Trac Lok 3.54 84.5 & 85 1/2-ton 610198-4 Standard 3.54 84.5 & 85 1/2-ton 610198-5 Standard 3.54 84.5 & 85 1/2-ton 610198-9 Standard 3.07 84.5 & 85 1/2-ton 610198-10 Standard 3.07 84.5 & 85 1/2-ton 610198-11 Trac Lok 3.54 84.5 & 85 1/2-ton 610198-12 Standard 3.54 84.5 & 85 1/2-ton 610198-13 Standard 3.54 84.5 & 85 1/2-ton 610198-14 Standard 3.50 84.5 & 85 1/2-ton 610198-15 Standard 3.50 84.5 & 85 1/2-ton 610198-16 Trac Lok 3.50 84.5 & 85 1/2-ton 610198-17 Standard 4.09 84.5 & 85 1/2-ton 610198-18 Trac Lok 4.09 84.5 & 85 1/2-ton 610197-1 Standard 3.54 84.5 & 85 F150 SnowPlow 610197-4 Standard 3.54 84.5 & 85 F150 SnowPlow 610197-5 Standard 3.50 84.5 & 85 F150 SnowPlow 610199-1 Standard 3.54 84.5 & 85 3/4-ton 610199-2 Standard 3.54 84.5 & 85 3/4-ton 610199-3 Standard 3.54 84.5 & 85 3/4-ton 610199-4 Standard 3.54 84.5 & 85 3/4-ton 610199-5 Standard 3.54 84.5 & 85 3/4-ton 610199-6 Standard 4.09 84.5 & 85 3/4-ton 610199-7 Trac Lok 3.54 84.5 & 85 3/4-ton 610199-8 Standard 4.09 84.5 & 85 3/4-ton 610199-9 Trac Lok 4.09 84.5 & 85 3/4-ton 610199-10 Trac Lok 4.09 84.5 & 85 3/4-ton 610229-1 Standard 3.54 85 3/4-ton 610229-2 Standard 3.54 85 3/4-ton 610229-3 Standard 3.54 85 3/4-ton 610229-4 Trac Lok 3.54 85 3/4-ton 610229-5 Standard 4.09 85 3/4-ton 610229-6 Trac Lok 4.09 85 3/4-ton 610231-1 Standard 3.54 85 3/4 & 1-ton 610231-2 Standard 3.54 85 3/4 & 1-ton 610231-3 Standard 4.09 85 3/4 & 1-ton 610231-4 Trac Lok 3.54 85 3/4 & 1-ton 610231-5 Standard 4.09 85 3/4 & 1-ton 610231-6 Trac Lok 4.09 85 3/4 & 1-ton 610241-1 Standard 3.07 85.5 1/2-ton 610241-2 Trac Lok 3.54 85.5 1/2-ton 610241-3 Standard 3.54 85.5 1/2-ton 610241-4 Standard 3.50 85.5 1/2-ton 610241-5 Trac Lok 3.50 85.5 1/2-ton 610241-6 Standard 4.09 85.5 1/2-ton 610241-7 Trac Lok 4.09 85.5 1/2-ton 610242-1 Standard 3.54 85.5 F150 SnowPlow 610242-2 Standard 3.50 85.5 F150 SnowPlow 610243-1 Standard 3.54 88.5 3/4-ton 610243-2 Standard 3.54 88.5 3/4-ton 610243-3 Standard 4.09 88.5 3/4-ton 610243-4 Trac Lok 3.54 88.5 3/4-ton 610243-5 Standard 4.09 88.5 3/4-ton 610243-6 Trac Lok 4.09 88.5 3/4-ton 610261-1 Standard 3.07 86 1/2-ton 610261-2 Standard 3.54 86 1/2-ton 610261-3 Standard 3.50 86 1/2-ton 610262-1 Standard 3.07 86 1/2-ton 610262-2 Trac Lok 3.54 86 1/2-ton 610262-3 Standard 3.54 86 1/2-ton 610262-4 Standard 3.50 86 1/2-ton 610262-5 Trac Lok 3.50 86 1/2-ton 610262-6 Standard 4.09 86 1/2-ton 610262-7 Trac Lok 4.09 86 1/2-ton 610263-1 Standard 3.54 86 F150 SnowPlow 610263-2 Standard 3.50 86 F150 SnowPlow 610264-1 Standard 3.54 86 & 87 3/4-ton 610264-2 Standard 3.54 86 & 87 3/4-ton 610264-3 Standard 4.09 86 & 87 3/4-ton 610264-4 Trac Lok 3.54 86 & 87 3/4-ton 610264-5 Standard 4.09 86 & 87 3/4-ton 610264-6 Trac Lok 4.09 86 & 87 3/4-ton 610267-1 Standard 3.07 87 & 88 1/2-ton 610267-2 Trac Lok 3.54 87 & 88 1/2-ton 610267-3 Standard 3.54 87 & 88 1/2-ton 610267-4 Standard 3.50 87 & 88 1/2-ton 610267-6 Standard 4.09 87 & 88 1/2-ton 610268-1 Standard 3.07 87 & 88 1/2-ton 610268-2 Standard 3.54 87 & 88 1/2-ton 610266-1 Standard 3.54 87 & 88 SnowPlow 610266-2 Standard 3.50 87 & 88 SnowPlow 610306-1 Standard 3.54 88 3/4-ton 610306-2 Standard 4.09 88 3/4-ton 610309-1 Standard 3.07 88.5 F150 SnowPlow 610309-2 Trac Lok 3.54 88.5 F150 SnowPlow 610309-3 Standard 3.54 88.5 F150 SnowPlow 610309-4 Standard 4.09 88.5 F150 SnowPlow 610311-1 Standard 3.54 88.5 - 91 1/2-ton 610311-2 Standard 4.09 88.5 - 91 1/2-ton 610310-1 Standard 3.07 88.5 - 92 1/2-ton 610310-2 Standard 3.54 88.5 - 92 1/2-ton 610335-1 Standard 3.07 88.5 - 92 1/2-ton 610335-2 Trac Lok 3.54 88.5 - 92 1/2-ton 610335-3 Standard 3.54 88.5 - 92 1/2-ton 610335-4 Standard 4.09 88.5 - 92 1/2-ton 610407-1 Standard 3.07 92.5 1/2-ton 610407-3 Standard 3.54 92.5 1/2-ton 610408-1 Standard 3.07 92.5 1/2-ton 610408-3 Standard 3.54 92.5 1/2-ton 610408-4 Standard 4.09 92.5 1/2-ton 610408-6 Trac Lok 3.54 92.5 1/2-ton 610408-7 Standard 3.07 92.5 1/2-ton 610408-9 Standard 3.54 92.5 1/2-ton 610411-1 Standard 3.07 93 & 93.5 Bronco 610411-2 Trac Lok 3.54 93 & 93.5 Bronco 610411-3 Standard 3.54 93 & 93.5 Bronco 610411-4 Standard 4.09 93 & 93.5 Bronco 610411-7 Standard 3.07 93 & 93.5 Bronco 610411-8 Standard 3.54 93 & 93.5 Bronco 610414-1 Standard 3.07 93 & 93.5 F150 610414-3 Standard 3.54 93 & 93.5 F150 610414-4 Standard 4.09 93 & 93.5 F150 610414-6 Trac Lok 3.54 93 & 93.5 F150 610414-7 Standard 3.07 93 & 93.5 F150 610414-9 Standard 3.54 93 & 93.5 F150 610443-3 Standard 3.54 94 - 96 Bronco 610443-9 Standard 3.54 94 - 96 Bronco 610447-3 Standard 3.54 94 - 96 Bronco 610447-9 Standard 3.54 94 - 96 Bronco 610447-10 Standard 3.54 94 - 96 Bronco 610444-1 Standard 3.07 94 F150 610444-2 Standard 3.31 94 F150 610444-3 Standard 3.54 94 F150 610444-4 Standard 4.09 94 F150 610444-5 Trac Lok 3.31 94 F150 610444-6 Trac Lok 3.54 94 F150 610444-7 Standard 3.07 94 F150 610444-8 Standard 3.31 94 F150 610444-9 Standard 3.54 94 F150 610446-1 Standard 3.07 95 & 96 F150 610446-2 Standard 3.31 95 & 96 F150 610446-3 Standard 3.54 95 & 96 F150 610446-5 Trac Lok 3.31 95 & 96 F150 610446-6 Trac Lok 3.54 95 & 96 F150 610446-10 Standard 3.07 95 & 96 F150 610446-11 Standard 3.31 95 & 96 F150 610446-12 Standard 3.54 95 & 96 F150 610608-1 Standard 3.54 96.5 Bronco 610608-2 Standard 3.54 96.5 Bronco 610607-1 Standard 3.07 96.5 F150 610607-2 Standard 3.31 96.5 F150 610607-3 Standard 3.54 96.5 F150 610607-4 Standard 4.09 96.5 F150 610607-5 Trac Lok 3.31 96.5 F150 610607-6 Trac Lok 3.54 96.5 F150 610607-7 Standard 3.07 96.5 F150 610607-8 Standard 3.31 96.5 F150 610607-9 Standard 3.54 96.5 F150

|

|

|

Wheel Bearings Dry Packing the hub with grease will prevent this, even when fording deep water.  havack's '93 XLT Bronco

|

|

|

2-piece Inner Wheel Seal (Rolling Diaphragm Seal) used on late ~5/95~96 1/2-ton 4WDs. The pair is MotorCraft BRS23 or F5TZ-1S190-AA. The original-design rubber seal is MotorCraft BRS78; the revised rubber seal is BRS86; the steel seal is MotorCraft BRS85#6&7 in this diagram:  ERROR: It was NOT used on '93-94s, and can't be used on them without changing the spindle AND hub. The black seal slips onto the spindle. The side visible in this pic goes OUTboard against the smooth surface of the metal seal; the smaller ring slips over the spindle's base shoulder. APPLY GREASE to the larger lip or the wheel will squeak. Either wheel bearing grease, or silicone grease (preferred), or PTFE (teflon). See also:

|

|

|

Timken 710430 Inner Wheel Seal for 5/95-96 4WD 1/2-ton, and possibly some later heavier trucks

|

|

|

Before installing the inner wheel seal, add a ring of grease to keep the bearing full. This is correct disk-brake-rated high-temperature EP grease.

Front tone ring E7TZ2B409B (F37A-2C182-AC)

|

|

|

5/95-96 hub, '93-96 tone ring E7TZ2B409B (F37A-2C182-AC), & 5/95-96 inner wheel seal

|

|

|

SealingSurface.JPG | Hits: 3601 | Size: 88.97 KB | Posted on: 8/10/11 | Link to this image SealingSurface.JPG | Hits: 3601 | Size: 88.97 KB | Posted on: 8/10/11 | Link to this image

Take a few extra moments to remove any accumuated grime and then brush the sealing surface so the new seal will last. Note that this steering knuckle & shield (Left F4TZ-2K005-B, Right F4TZ-2K004-B) are specific to the '94-up floating caliper design, as indicated by the caliper bolt ear at the far R. Caliper bolt torque 30-36 N-m (22-27 lb-ft). Also note the spindle is NOT designed for the upgraded double-lip seal introduced 5/95.

|

|

|

It's worth the effort to clean off any accumulated grime, particularly from the base of the spindle where the inner wheel seal fits.

|

|

|

While the rotor is off the hub, make sure both sides of the flange are thoroughly clean & flat to prevent warping the rotors. It doesn't take much to ruin them.  For drums, only the outboard surface of the axle flange needs to be cleaned. But both sides of the drum must be cleaned.

|

|

|

'96 Bronco front hub parts

Front tone ring E7TZ2B409B (F37A-2C182-AC)

|

|

|

This is the grease I prefer for wheel bearings & general chassis use. I get it at the local O'Reilly store.

|

|

|

Pack bearings, then fill void between bearings with Castrol Pyroplex Blue, Mystick, or some other high-film-strength EP grease rated for disk brakes; NOT cheap grease as shown. Any air in this area will contract during deep fording, causing water to be sucked past the seals into the grease & bearings. Filling with grease prevents this.  .  DO NOT FILL THE HUB LOCKS. They need air space inside for their mechanisms to move, so they should only have a light coat of grease. Most modern hub locks should be merely dunked in ATF before installation. Read their included instructions.

|

|

|

BearingNutAdjustment.jpg | Hits: 15129 | Size: 53.09 KB | Posted on: 1/30/05 | Link to this image BearingNutAdjustment.jpg | Hits: 15129 | Size: 53.09 KB | Posted on: 1/30/05 | Link to this image

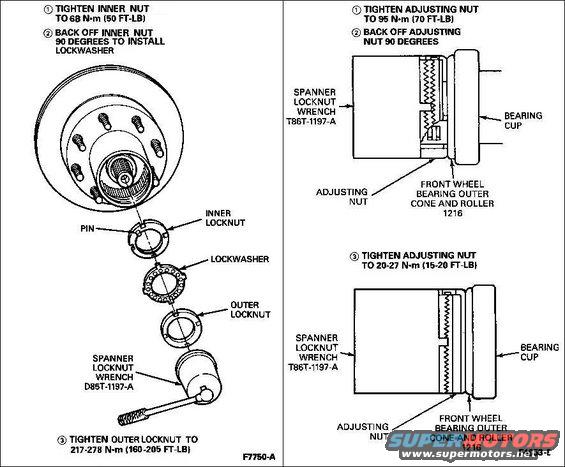

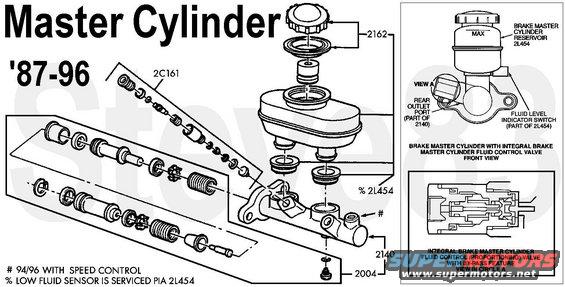

Wheel Bearing Nut adjustments. The L pane is the common 3-piece system, which requires either of these spanners:  The R pane is the rare 1-piece self-locking nut:  The text below describes the later hex nut. For '94-96 with the single large hex nut (3-screw auto hub lock caps OR any manual hub locks), follow this procedure: While rotating front disc brake hub and rotor, tighten until snug to seat wheel bearings. Back nut off 90 degrees (1/4 Turn). Tighten to 1.8 N-m (16 Lb-In), insert locking key, thrust washers, and C-clip. Refer to these:

|

|

|

The L spanner is stronger & less likely to slip off a nut, but it won't work on a self-locking nut. Both are 2-3/8" round spanner sockets with 4 square teeth. Later auto hub locks use a 2-3/8" rounded hex socket.

|

|

|

HubNutSelfLocking.jpg | Hits: 8473 | Size: 22.75 KB | Posted on: 1/29/05 | Link to this image HubNutSelfLocking.jpg | Hits: 8473 | Size: 22.75 KB | Posted on: 1/29/05 | Link to this image

Rare self-locking hub nut used in the late '80s. Its locking tooth in the center often gets bent inward by improper installation or removal. Make sure it protrudes enough to fully engage the slot on the spindle. If not, it will work its way loose. When installing or removing this nut, make sure the outer cage does NOT spin; the tooth in the center must remain in the spindle's groove. This explains how to re-install it:

|

|

|

This '95 Bronco was factory-equipped with 3-screw auto hub locks, but a previous owner swapped in these light-duty Warn manuals. The current owner thought the wheel bearings were going bad, but I found the nut key had fallen out of place, fouling into the rotating hub lock body, and allowing the bearing adjusting nut to back off. I temporarily straightened the key & reinstalled it (after changing the bearings & rotor anyway), but he ordered the older-style nuts & installed them himself later.

|

|

|

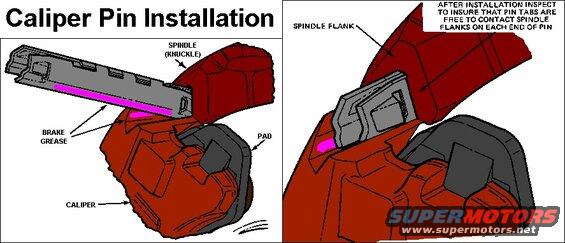

CaliperPinstall.jpg | Hits: 308 | Size: 37.67 KB | Posted on: 5/31/24 | Link to this image CaliperPinstall.jpg | Hits: 308 | Size: 37.67 KB | Posted on: 5/31/24 | Link to this image